Shock Testing

Shock testing is a critical process used across various industries to evaluate the resilience and reliability of products subjected to dynamic mechanical forces. This comprehensive guide explores the fundamentals of shock testing, emphasizing the significance of classical shock pulses, the types of shock testing machines, and the key steps involved in conducting shock tests on electrodynamic shakers.

Vibration Analysis: Good vs Bad Vibration Data

In the realm of vibration analysis, the crucial distinction between reliable and misleading data holds paramount importance. Delving into the causes and manifestations of erroneous data, alongside strategies for elevating data integrity, is pivotal for future improvements in data quality.

Ensuring Quality in Testing and Calibration

This comprehensive guide emphasizes the importance of accuracy and precision in testing and calibration processes. Calibration plays a crucial role in achieving accuracy by comparing instrument readings to known standards. The article also addresses common challenges, including equipment limitations, environmental factors, human errors, calibration intervals, and traceability issues. To ensure quality, adopting best practices like regular calibration, proper training, method validation, and continuous improvement is essential. These measures lead to reliable data, informed decision-making, and higher standards across various industries.

Fatigue Life Test on Battery

The world is witnessing a significant shift towards renewable energy and sustainable technology. As a result, the demand for reliable and long-lasting energy storage solutions, such as batteries, is on the rise. One crucial aspect that determines the performance and durability of a battery is its fatigue life. The fatigue life of a battery refers to the number of charge and discharge cycles it can endure before its capacity significantly degrades. To ensure the efficiency and longevity of batteries, manufacturers conduct fatigue life tests, which are instrumental in determining their real-world performance. In this article, we will explore the process of conducting a fatigue life test on batteries and its significance in various applications.

A Comprehensive Guide to Velocity-Type Vibration Sensor Calibration Checks

In the world of industrial applications, velocity-type vibration sensors serve as crucial guardians, monitoring machinery health and ensuring safe operations. To guarantee precise measurements, regular calibration checks are essential. These checks verify the sensor's accuracy and sensitivity, helping to detect faults early and optimize maintenance. A case study involving a gas turbine in a power plant highlights how calibration checks lead to enhanced efficiency and cost savings. By fine-tuning the sensor's sensitivity, engineers ensure continued reliability, making calibration checks a proactive approach to industrial safety and performance.

Simcenter STAR-CCM+ Helps Energy Consultancy Firm Improve Gas Turbine Blade Cooling

Gas turbine efficiency improvement relies on increasing temperatures at the combustor exit and high-pressure turbine stage inlet. However, this poses a challenge as higher temperatures can endanger the integrity of turbine components. To address this issue, film cooling techniques have been adopted, where cool air is bled from the compressor stage and directed through small holes in the turbine blade and vane walls, creating a thin, cool insulating layer.

French Automaker Optimizes Battery Pack with Simcenter Amesim

In the pursuit of excellence and innovation, PSA Peugeot Citroën embraced the power of Siemens Digital Industries Software's Simcenter™. The comprehensive simulation and testing capabilities enabled them to revolutionize the automotive industry and set new standards for vehicle performance, safety, and environmental sustainability. As technology continues to advance, embracing cutting-edge solutions like Simcenter™ will be crucial for any automotive manufacturer seeking to stay ahead in this dynamic and competitive landscape.

Siemens Simcenter SCADAS XS 6: Enhancing Data Acquisition and Analysis

Siemens Simcenter SCADAS XS 6 stands as a powerful solution for engineers seeking efficient data acquisition and analysis capabilities. With its high-speed data acquisition, scalability, real-time monitoring, and advanced signal processing features, SCADAS XS 6 empowers engineers to make informed decisions and optimize the performance of various systems. Whether in the automotive, aerospace, energy, or structural domains, SCADAS XS 6 delivers valuable insights for improving safety, reliability, and efficiency.

Shock Response Spectrum Analysis Approach for Optimal Design of Electronic Devices

The Shock Response Spectrum (SRS) is a vital tool in the design of electronic devices. It provides engineers with a graphical representation of the device's response to shock loads, helping them optimize its shock resistance. By analyzing the SRS curve, engineers can identify critical frequencies, make informed design decisions, and improve reliability. The SRS analysis ensures cost-effective design, reduces the risk of failure during shocks, and enhances overall device performance.

Understanding the Non-Synchronous Defect Frequencies in Rolling Element Bearings

Rolling element bearings play a vital role in machinery, but non-synchronous defect frequencies can pose challenges. Manufacturing imperfections, misalignment, and operating conditions contribute to these irregular vibrations. To mitigate risks, precision manufacturing, accurate alignment, and condition monitoring are crucial. Understanding and addressing non-synchronous defect frequencies ensure optimal performance and reliability of bearings.

How Do You Test a Vibration Accelerometer Sensor?

Testing vibration accelerometer sensors are a vital aspect of ensuring accurate and reliable vibration measurements. By following the outlined steps, best practices, and safety precautions, you can effectively evaluate the performance of your sensor and make informed decisions based on the collected data. Regular testing helps maintain optimal equipment performance, prevent failures, and ultimately contribute to the overall productivity and efficiency of your operations.

Sand & Dust Test Chambers

In this article, we will explore the significance of sand and dust testing, how these test chambers work, their benefits, industries that benefit from them, key features to consider, factors to evaluate when choosing a test chamber, and real-world case studies. So, let's dive in and discover how sand and dust test chambers play a vital role in ensuring product quality and performance.

What Problems Do Vibration Engineers Encounter?

Vibration engineering plays a crucial role in various industries, including aerospace, automotive, civil engineering, and manufacturing. Engineers in this field face unique challenges that demand their expertise in understanding, analyzing, and controlling vibrations. In this article, we will explore the common problems encountered by vibration engineers and the strategies they employ to address them.

How Accurate Are Load Cells: A Comprehensive Guide

Load cells are precision instruments used to measure force or weight in various industries. But how accurate are load cells? This comprehensive guide delves into the world of load cell accuracy, exploring its importance, factors influencing accuracy, common specifications, and frequently asked questions. Discover the key elements that can affect load cell accuracy, such as environmental conditions, mounting and installation, overload protection, signal conditioning, and regular calibration. By understanding load cell accuracy, you can ensure precise measurements and reliable results in your applications. Gain insights into the factors that influence load cell accuracy and learn how to optimize it for accurate and dependable measurements.

Simcenter 3D FE Model Correlation

Simcenter™ 3D FE Model Correlation provides engineers with the necessary tools to align geometric models, compare modes from different solutions, visualize mode shapes side-by-side, and calculate correlation metrics. This enables them to gain a comprehensive understanding of how closely the simulation aligns with the physical test data. By leveraging this software, engineers can confidently assess the accuracy and reliability of their simulations, thereby improving the overall design and development process.

Vibration Testing for Electronic Parts and EEE Components

In today's fast-paced world, electronic parts and EEE (Electrical and Electronic Equipment) components play a critical role in various industries. From automotive vehicles to aerospace systems and consumer electronics, these components need to withstand the rigors of real-world vibrations. This is where vibration testing comes into play. By subjecting electronic parts to controlled vibrations, engineers can evaluate their durability, reliability, and performance. In this article, we delve into the importance of vibration testing for electronic parts and EEE components. We explore its applications in different industries, the challenges involved, best practices, case studies, and future trends, and provide answers to frequently asked questions.

Experimental Characterization and Simulation of Vibration Environmental Test

This article covers the basics of vibration environmental testing, including the different types of vibration simulation methods, test equipment and instrumentation, test procedures, vibration measurement techniques, data acquisition and analysis, and test standards and guidelines. It also discusses the applications of vibration environmental testing in various industries and future trends in the field, such as emerging technologies, integration of test and simulation, and use of artificial intelligence and machine learning. By understanding the fundamentals of vibration environmental testing and staying up-to-date on the latest trends and technologies, manufacturers and engineers can ensure that their products are reliable, durable, and high-performing in a variety of real-world environments.

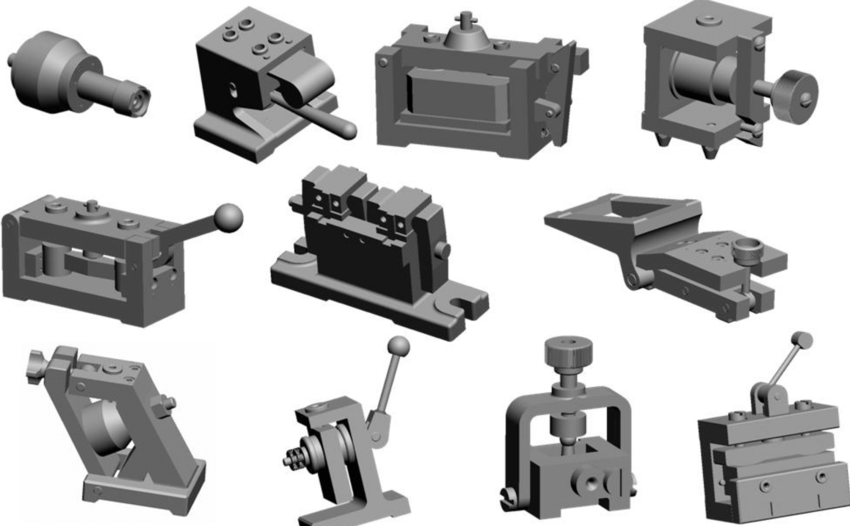

Design Principles of Jigs and Fixtures for Improved Manufacturing Efficiency and Quality

Jigs and fixtures are essential tools for increasing efficiency, reducing costs, and improving product quality in manufacturing processes. In this article, we will discuss the basic principles of jigs and fixtures design, including their purpose, types, and components. By understanding these principles, manufacturers can improve the accuracy and consistency of their machining and assembly processes, resulting in higher-quality products and increased profitability.

Predictive Maintenance for Shaker Systems: Maximizing Equipment Lifespan

Predictive Maintenance for Shaker Systems is a powerful tool that can help companies improve the reliability and efficiency of their equipment. By using data analytics and machine learning to predict when maintenance should be performed, companies can address potential issues before they become major problems, improving safety and productivity. In this article, we will explore the benefits of Predictive Maintenance for Shaker Systems, how companies can get started with it, and some common FAQs associated with its implementation.

Importance of Vibration Testing Maintenance & Genuine Parts

Preventive maintenance programs, genuine spare parts, and technical support are critical components for ensuring the accurate and safe operation of vibration testing systems. Preventive maintenance programs can help catch potential issues before they become significant problems, while using genuine spare parts can help ensure accurate measurements and reduce the risk of equipment failure or safety hazards. Technical support can provide operators with training, guidance, and troubleshooting assistance to help optimize the system's performance