Essential Design Principles of Jigs and Fixtures for Enhanced Manufacturing Efficiency and Quality

In the dynamic world of manufacturing, achieving efficiency and maintaining high quality are paramount. One of the key elements in attaining these goals is the effective use of jigs and fixtures.

Jig or Fixture Design Problems and Solutions

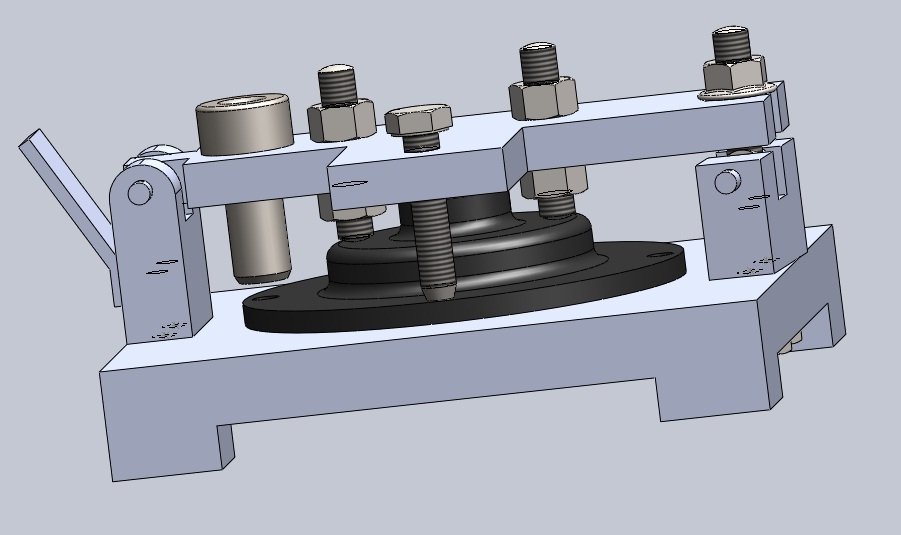

Test fixture resonance. Prior to test, a test fixture survey should be conducted to ensure that the structural characteristics of the test fixture do not introduce uncontrollable resonances into the test setup. The survey may be experimental or analytical. If problematic resonances are identified, modifications should be made to the test fixture to shift the resonance beyond the frequency range of the test or to dampen the resonance in order to minimize the effect on the test.

Tackling Jig and Fixture Design Dilemmas

In engineering, designing a vibration test fixture is crucial, as highlighted by MIL-STD-810G-Method 514.6. Inadequate designs can lead to costly testing issues, but by keeping fixtures lightweight and stiff, and using materials like aluminum or magnesium, engineers can minimize resonance problems. Finite Element Model (FEM) simulations, especially normal mode simulations, provide valuable insights for optimal design.

Design Principles of Jigs and Fixtures for Improved Manufacturing Efficiency and Quality

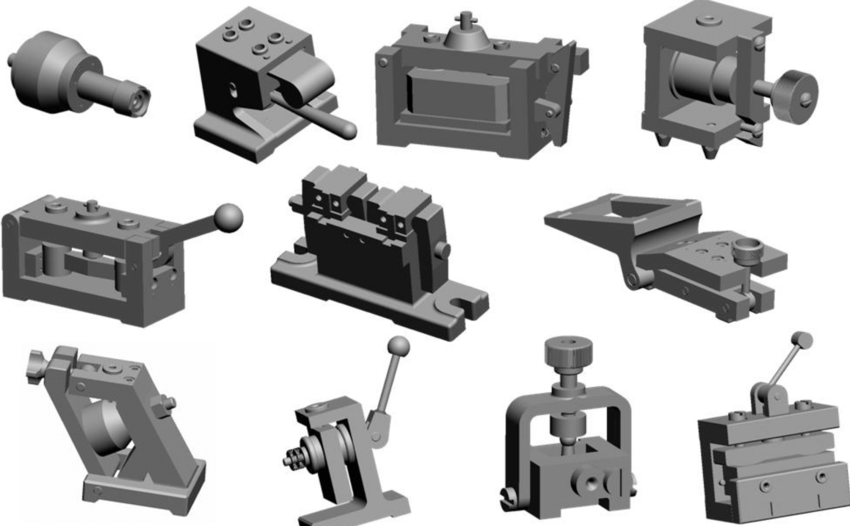

Jigs and fixtures are essential tools for increasing efficiency, reducing costs, and improving product quality in manufacturing processes. In this article, we will discuss the basic principles of jigs and fixtures design, including their purpose, types, and components. By understanding these principles, manufacturers can improve the accuracy and consistency of their machining and assembly processes, resulting in higher-quality products and increased profitability.

Easy strength and Fatigue Analysis with Simcenter

Strength and fatigue analysis made easier in simulations. Templates for fatigue analysis and their strength-only counterparts are relatively recent additions to Simcenter 3D. As a result, many engineers are unaware of them or the benefits that they can bring.

The strength analysis case provides static and fatigue strength analysis for any finite element set-ups created in Simcenter 3D. It is fully integrated into finite element workflows and fatigue workflows. You can use material data from a material database (inherited from finite element analysis) or directly in the analysis case.

Practical Aspect on Fixture Design Calculation

Ideally, the vibration test fixture should be designed to be; As light as possible, and As stiff as possible. But in the real vibration testing world, there are a lot of constraint that we need to consider and then we need to find and optimum point, that can balance all required aspects such as cost, timeline, etc. In this article we are discussing some practical aspects that we may need to consider during the design process of our vibration fixture.

Jig and Fixture Design

A jig and fixture are work-holding devices used in machining operations as an agent of support. They secure, support, or mount a workpiece correctly on the parts of a CNC machine. They are very important since they aid smoother manufacturing operations and productivity among other advantages. In this article, you will learn about both Jigs and fixtures, their types, uses, and manufacturing.