Essential Design Principles of Jigs and Fixtures for Enhanced Manufacturing Efficiency and Quality

In the dynamic world of manufacturing, achieving efficiency and maintaining high quality are paramount. One of the key elements in attaining these goals is the effective use of jigs and fixtures.

Jig or Fixture Design Problems and Solutions

Test fixture resonance. Prior to test, a test fixture survey should be conducted to ensure that the structural characteristics of the test fixture do not introduce uncontrollable resonances into the test setup. The survey may be experimental or analytical. If problematic resonances are identified, modifications should be made to the test fixture to shift the resonance beyond the frequency range of the test or to dampen the resonance in order to minimize the effect on the test.

Mastering Productivity in 2024: A Guide for Vibration Engineers

Gear up for 2024 as a vibration engineer! Our blog is your go-to guide for staying productive in the evolving landscape. Uncover insights, tips, and solutions to tackle challenges like complex machinery, time constraints, and the integration of AI and IoT. Learn from pioneers, embrace new technologies, and conduct the machinery symphony with confidence. Stay ahead in the dynamic era of Vibration Engineering

Ensuring a Silent Holiday: A Guide to Caring for Your Vibration Shaker

If you're heading off for a well-deserved holiday break, make sure your vibration shaker is not left out in the cold. Our comprehensive guide provides essential tips to safeguard your equipment during your absence, ensuring a seamless return to work. From a detailed inspection to practical steps for storage, we've got you covered. Read more to discover how a little pre-holiday care can go a long way in preserving the longevity and efficiency of your vibration shaker.

Tackling Jig and Fixture Design Dilemmas

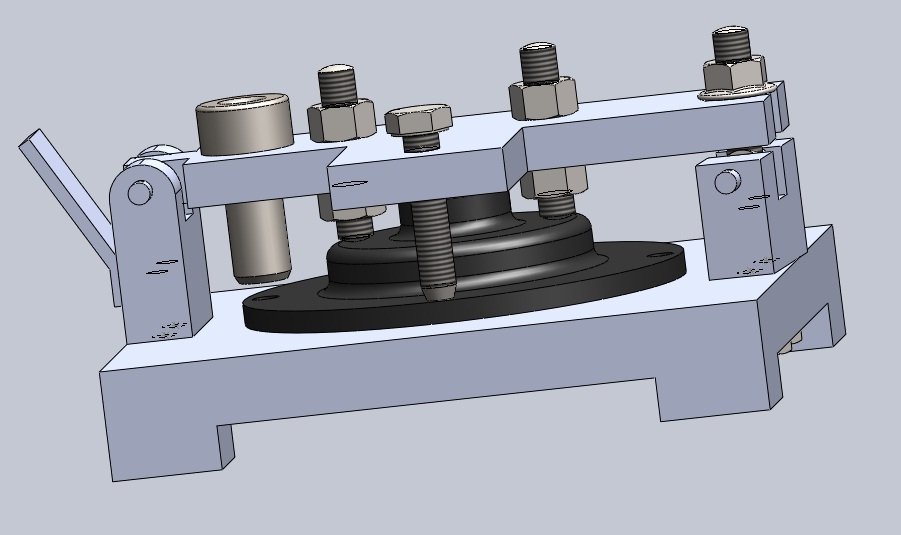

In engineering, designing a vibration test fixture is crucial, as highlighted by MIL-STD-810G-Method 514.6. Inadequate designs can lead to costly testing issues, but by keeping fixtures lightweight and stiff, and using materials like aluminum or magnesium, engineers can minimize resonance problems. Finite Element Model (FEM) simulations, especially normal mode simulations, provide valuable insights for optimal design.

What Problems Do Vibration Engineers Encounter?

Vibration engineering plays a crucial role in various industries, including aerospace, automotive, civil engineering, and manufacturing. Engineers in this field face unique challenges that demand their expertise in understanding, analyzing, and controlling vibrations. In this article, we will explore the common problems encountered by vibration engineers and the strategies they employ to address them.

Vibration Testing for Electronic Parts and EEE Components

In today's fast-paced world, electronic parts and EEE (Electrical and Electronic Equipment) components play a critical role in various industries. From automotive vehicles to aerospace systems and consumer electronics, these components need to withstand the rigors of real-world vibrations. This is where vibration testing comes into play. By subjecting electronic parts to controlled vibrations, engineers can evaluate their durability, reliability, and performance. In this article, we delve into the importance of vibration testing for electronic parts and EEE components. We explore its applications in different industries, the challenges involved, best practices, case studies, and future trends, and provide answers to frequently asked questions.

Experimental Characterization and Simulation of Vibration Environmental Test

This article covers the basics of vibration environmental testing, including the different types of vibration simulation methods, test equipment and instrumentation, test procedures, vibration measurement techniques, data acquisition and analysis, and test standards and guidelines. It also discusses the applications of vibration environmental testing in various industries and future trends in the field, such as emerging technologies, integration of test and simulation, and use of artificial intelligence and machine learning. By understanding the fundamentals of vibration environmental testing and staying up-to-date on the latest trends and technologies, manufacturers and engineers can ensure that their products are reliable, durable, and high-performing in a variety of real-world environments.

Design Principles of Jigs and Fixtures for Improved Manufacturing Efficiency and Quality

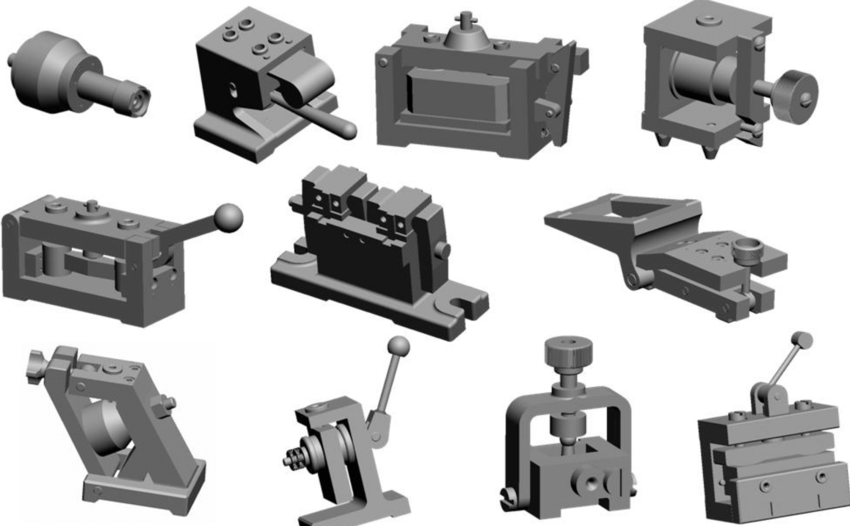

Jigs and fixtures are essential tools for increasing efficiency, reducing costs, and improving product quality in manufacturing processes. In this article, we will discuss the basic principles of jigs and fixtures design, including their purpose, types, and components. By understanding these principles, manufacturers can improve the accuracy and consistency of their machining and assembly processes, resulting in higher-quality products and increased profitability.

Vibration Testing in the Marine Industry: Why It Matters

Vibration testing is a critical aspect of ensuring the safety and reliability of marine equipment and structures. In the dynamic and demanding marine environment, vibration can be a significant source of equipment failure, leading to costly downtime, repairs, and safety hazards. By subjecting equipment to simulated vibration conditions, potential issues can be identified before they cause costly downtime or safety hazards. Learn more in our blog post.

Understanding the Importance of Vibration Testing of Electronic Components

Vibration testing is a crucial aspect of ensuring the reliability and durability of electronic components. This testing involves subjecting the components to mechanical stress and vibration to simulate the conditions they may encounter during their intended use. By identifying potential flaws early in the development process, manufacturers can improve the quality and safety of their products and reduce the risk of failure. At AscendTech Group, we offer a range of vibration testing systems and services to help ensure the success of your electronic components.

The Importance of Shock and Vibration Compliance Tests in Product Design

Shock and Vibration Compliance Testing is an essential part of product development for manufacturers across various industries. These tests ensure that products can withstand environmental stressors and meet necessary compliance standards, providing peace of mind to manufacturers and customers alike. At our ISO 17025 accredited laboratory SAC Singlas, our experienced team of engineers uses the latest testing equipment to conduct these tests efficiently and effectively. By partnering with us for your testing needs, you can ensure that your products meet compliance standards, are reliable, safe, and meet customer expectations.

What Factors Affect the Severity of the Drop Testing?

The severity of the drop testing can be affected by a variety of factors, including the height of the fall, the surface on which the object lands, and the shape and composition of the object.

Shape and composition are two additional factors that affect severity. Objects with sharp edges or points are more likely to suffer damage than those that are smooth and round. Additionally, objects made of sturdy materials are less likely to break than those made of weaker materials.

Drop Test Standards for Consumer Electronics

Are you a consumer electronics manufacturer looking to know more about the drop test standards that your products need to meet? You’ve come to the right place. We will discuss the various drop test standards that consumer electronics need to pass in order to be considered safe for use by consumers. We will also look at how these tests are conducted, their purpose, and the consequences of not meeting these standards. Finally, we will provide tips on how manufacturers can go about ensuring their products pass these tests. Read on to learn more!

Why Do We Need to Perform Vibration Test?

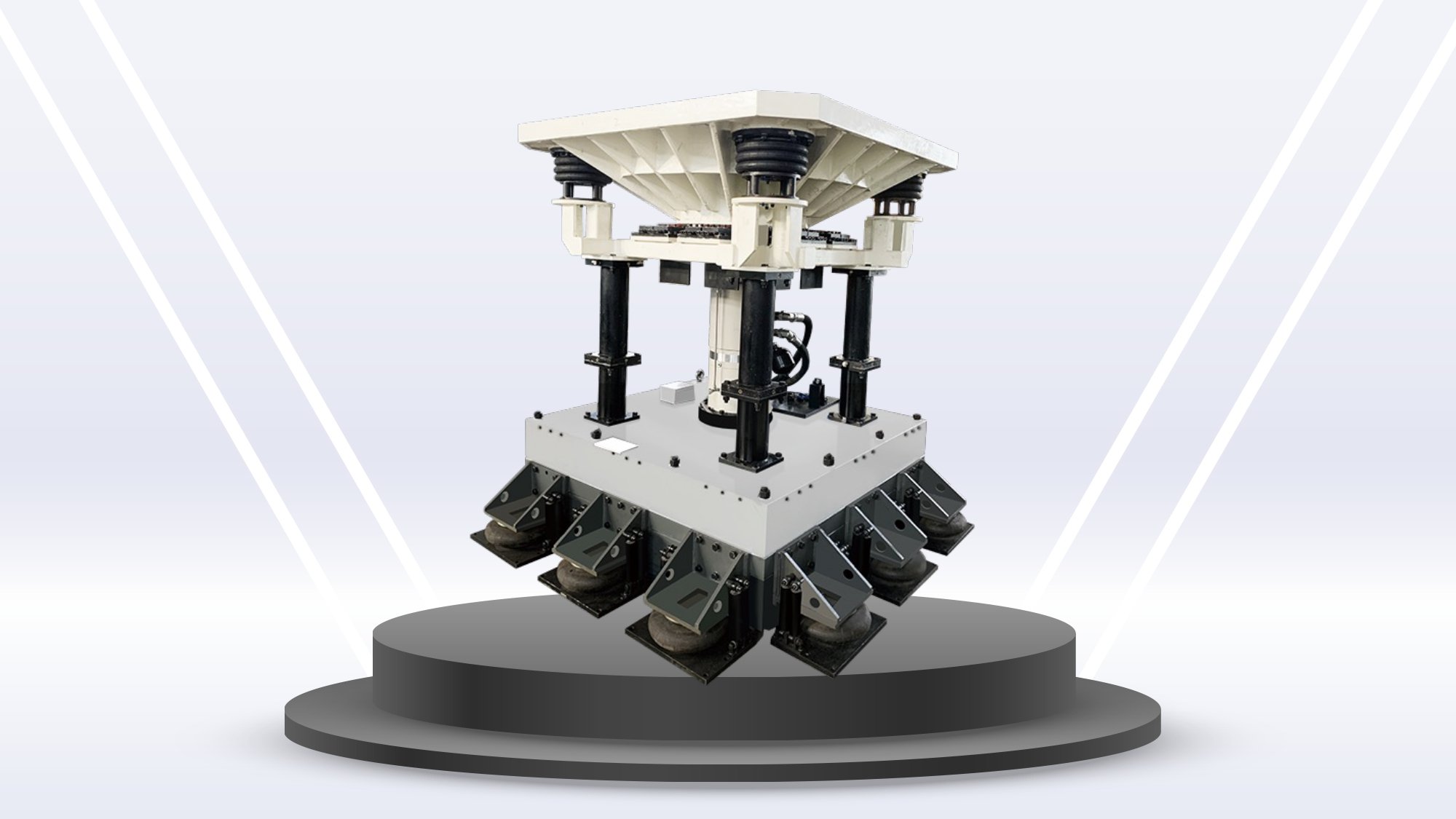

If the prototype cost of our product is relatively small or if development time of our product does not really matter, due to no competition, then we may consider the vibration testing is not really relevant. But if our product is part of vital system in automotive where development time is getting shorter and crucial, or part of vital system in aerospace where prototype cost is relatively expensive and where safety has become very big issue, then having a vibration testing system may be considered as vital investment.

Practical Aspect on Fixture Design Calculation

Ideally, the vibration test fixture should be designed to be; As light as possible, and As stiff as possible. But in the real vibration testing world, there are a lot of constraint that we need to consider and then we need to find and optimum point, that can balance all required aspects such as cost, timeline, etc. In this article we are discussing some practical aspects that we may need to consider during the design process of our vibration fixture.

Jig and Fixture Design

A jig and fixture are work-holding devices used in machining operations as an agent of support. They secure, support, or mount a workpiece correctly on the parts of a CNC machine. They are very important since they aid smoother manufacturing operations and productivity among other advantages. In this article, you will learn about both Jigs and fixtures, their types, uses, and manufacturing.

How Do You Measure a Vibration Test?

Vibration testing is a key part of quality control for many products. It helps ensure that products can withstand the rigors of shipping and handling, as well as everyday use. There are many different ways to measure vibration, but the most important thing is to choose a method that will give you accurate results.

What Is a Hydraulic Vibration Shaker Used For?

Vibration shakers are versatile tools that can be used for a variety of purposes. Hydraulic vibration shakers are particularly useful for simulating real-world conditions and testing products under extreme conditions. If you're looking for a way to test your products under the most realistic conditions possible, a hydraulic vibration shaker is an excellent option to consider.

What Is Vibration And Noise Control?

Vibration and noise control are important methods of reducing or eliminating unwanted sounds and vibrations. There are many different ways to achieve vibration and noise control, and the most effective approach will vary depending on the specific situation. In some cases, simple measures like increasing the mass of a structure can be enough to dramatically reduce vibration and noise levels. In other cases, more complex methods like active noise cancellation may be necessary. Whatever the approach, it is important to consider both vibration and noise control when trying to create a quiet environment.