Remote diagnostic services reaching new heights with wireless sensors

A motor repair shop is deeply engaged in providing top-tier monitoring solutions and reliability services to its customers. Serving central and western Germany, they cater to a wide range of applications, from chemical industries to facility management, effectively managing diverse critical situations.

Unlock Operational Excellence with ISO 9001 Quality Management Certification

Meeting customer expectations, improving operational efficiency, and ensuring consistent performance are key drivers of success. The ISO 9001 Quality Management System (QMS) offers businesses a proven framework to achieve these goals and much more.

Tackling Life-Threatening Hazards in Explosive Environments with Minebea Intec Solutions

In industries such as chemical, pharmaceutical, cosmetics, and food production, the air often hides a dangerous secret—flammable gases and combustible dust particles. These invisible threats, when combined with a single ignition spark, have the potential to trigger catastrophic explosions, endangering both human lives and production facilities.

Combat Corruption with ISO 37001 Anti-Bribery Management System Training

In today’s global business environment, integrity and ethical practices are non-negotiable. Bribery and corruption not only tarnish reputations but also expose organizations to severe legal and financial risks.

Safeguard Your Business with ISO/IEC 27001 Information Security Management Training from AscendTech

In an era of increasing digital threats and data breaches, safeguarding sensitive information has never been more critical.

Drive Sustainable Growth with ISO 14001 Environmental Management Training at AscendTech

In an era where environmental responsibility is no longer optional but essential, organizations are increasingly turning to robust environmental management frameworks.

Unlock Business Success with ISO 9001 Quality Management Training from AscendTech

As the world’s most widely recognized quality management standard, ISO 9001 provides a solid foundation for building efficient processes that lead to sustained success.

Unlock Career Advancement with Self-Study ISO Certification Courses by AscendTech and PECB

At AscendTech, we offer Self-Study ISO Certification Courses powered by PECB, designed to provide you with the flexibility and credentials needed to boost your career and enhance your organization's performance.

The Power of Precision: Mobile Weighing Solutions for Pharmaceutical Manufacturing

In today’s fast-paced pharmaceutical industry, precision, flexibility, and efficiency are more critical than ever. Manufacturing facilities are constantly looking for solutions that not only streamline their processes but also ensure the highest standards of accuracy. One excellent example is the mobile weighing system developed by Minebea Intec, combining Combics 3 indicators with high-resolution platforms.

The Leverage Effect: Exploring Impact FRF and Virtual Point Transformation (VPA)

In the world of engineering and product design, accurately predicting and mitigating noise, vibration, and harshness (NVH) issues is critical. Two powerful tools that engineers use to address these challenges are Impact Frequency Response Function (FRF) and Virtual Point Transformation (VPA).

Ensuring Precision with Calibration Services and Measurement Across Industries

Calibration services and measurement are critical components of many industries, including healthcare, transportation, and manufacturing. Calibration refers to the process of verifying and adjusting the accuracy of measurement equipment, while measurement involves quantifying a physical property, such as length, mass, or temperature. In this article, we will explore the importance of calibration services and measurement.

Understanding NVH Prediction: The Role of Modal Analysis in the Automotive Industry

NVH (noise, vibration, and harshness) prediction is a critical process in the automotive industry to ensure customer satisfaction, safety, and compliance with regulatory requirements.

How to Effectively Test a Vibration Accelerometer Sensor

Vibration accelerometer sensors play a crucial role in a wide range of applications, from monitoring machinery health to enhancing the performance of consumer electronics. Ensuring these sensors function accurately is vital for reliable data collection and analysis.

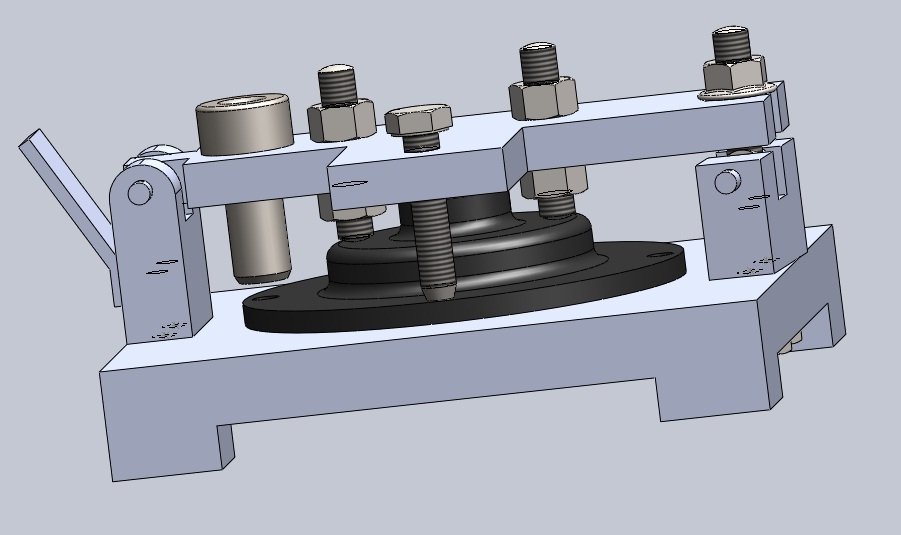

Essential Design Principles of Jigs and Fixtures for Enhanced Manufacturing Efficiency and Quality

In the dynamic world of manufacturing, achieving efficiency and maintaining high quality are paramount. One of the key elements in attaining these goals is the effective use of jigs and fixtures.

Benefits of ISTA 6 Compliance for Packaging in E-Commerce

The rapid growth of e-commerce has revolutionized the way consumers purchase goods. This shift, while convenient for consumers, poses significant challenges for businesses, particularly in ensuring products arrive at their destinations intact. One crucial solution to mitigate these challenges is adhering to ISTA 6 compliance for packaging.

Advancements in Thermal Comfort Simulations for Vehicle Cabins

Thermal comfort within vehicle cabins is a critical aspect of automotive design, influencing both the user experience and the efficiency of climate control systems. Traditional methods of assessing and improving thermal comfort have been largely empirical, relying on extensive physical testing.

The Critical Role of Vibration Sensors in Industry 4.0

In the era of Industry 4.0, the integration of smart technologies into industrial operations is not just a trend but a fundamental shift in how businesses maintain operational efficiency and reliability. Among these technologies, vibration sensors play a pivotal role, especially in the realms of predictive maintenance and condition monitoring across various industries.

Understanding Load Cell Varieties and Their Applications

Load cells are critical components in various industries for accurate weight measurement. These devices convert the mechanical force exerted by an object into an electrical signal, serving as the heart of electronic scales and other weighing systems.

Jig or Fixture Design Problems and Solutions

Test fixture resonance. Prior to test, a test fixture survey should be conducted to ensure that the structural characteristics of the test fixture do not introduce uncontrollable resonances into the test setup. The survey may be experimental or analytical. If problematic resonances are identified, modifications should be made to the test fixture to shift the resonance beyond the frequency range of the test or to dampen the resonance in order to minimize the effect on the test.

Acoustic Testing

Acoustic Testing is performed to determine if the material can resist the specified Acoustic environment. It must resist this environment without degradation of its functional performance and/or structural integrity. Acoustic Testing or Acoustic Emission Testing is the measurement of sound emissions radiating from the equipment under test. In other words, how loud is the equipment?