Essential Design Principles of Jigs and Fixtures for Enhanced Manufacturing Efficiency and Quality

In the dynamic world of manufacturing, achieving efficiency and maintaining high quality are paramount. One of the key elements in attaining these goals is the effective use of jigs and fixtures. These tools play a critical role in manufacturing processes, providing support, stability, and precision. This article explores the essential design principles of jigs and fixtures that can significantly enhance manufacturing efficiency and quality.

Understanding Jigs and Fixtures

Before diving into the design principles, it’s important to distinguish between jigs and fixtures:

Jigs: These are custom-made tools used to control the location and motion of another tool. They guide the cutting or drilling tools during manufacturing, ensuring precision and consistency.

Fixtures: These are support devices used to hold workpieces in place during manufacturing processes. Unlike jigs, fixtures do not guide the tools but provide stability and support.

Key Design Principles

To maximize the efficiency and quality of manufacturing processes, the design of jigs and fixtures should adhere to several fundamental principles:

1. Accuracy and Precision

The primary function of jigs and fixtures is to ensure that workpieces are machined accurately and precisely. This requires a high level of design accuracy to ensure that the tools align perfectly with the workpieces. Precision in design helps maintain consistent quality and reduces the likelihood of errors during manufacturing.

2. Simplicity

Simplicity is a critical design principle for jigs and fixtures. The design should be straightforward and easy to understand, allowing operators to use the tools with minimal training. Simple designs also facilitate easier maintenance and quicker setup times, contributing to overall efficiency.

3. Robustness and Durability

Jigs and fixtures must be designed to withstand the rigors of the manufacturing environment. This means selecting materials that are durable and capable of resisting wear and tear. Robust designs ensure that the tools maintain their accuracy and precision over extended periods, reducing downtime and maintenance costs.

4. Interchangeability

In manufacturing, it’s common to produce multiple parts or products that require similar processes. Designing jigs and fixtures to be interchangeable allows them to be used for different workpieces without the need for extensive modifications. This flexibility enhances productivity and reduces the need for multiple sets of tools.

5. Ergonomics and Safety

Ergonomic design is crucial for ensuring the safety and comfort of operators. Jigs and fixtures should be designed to minimize operator fatigue and reduce the risk of injury. This involves considering factors such as the weight of the tools, ease of handling, and operator posture during use.

6. Ease of Maintenance

To ensure longevity and consistent performance, jigs and fixtures should be designed for easy maintenance. This includes incorporating features that allow for quick cleaning, inspection, and replacement of worn components. Easy maintenance helps minimize downtime and keeps the manufacturing process running smoothly.

Benefits of Effective Jig and Fixture Design

Adhering to these design principles offers several benefits that enhance manufacturing efficiency and quality:

1. Increased Productivity

Effective jigs and fixtures streamline manufacturing processes, reducing the time required for setup and operation. This leads to increased productivity as more workpieces can be processed in a shorter time frame.

2. Consistent Quality

By ensuring that each workpiece is machined accurately and precisely, jigs and fixtures help maintain consistent quality across production runs. This consistency reduces the likelihood of defects and improves overall product quality.

3. Reduced Waste

Accurate and precise machining reduces the occurrence of errors and defects, leading to less waste. This not only saves material costs but also contributes to more sustainable manufacturing practices.

4. Enhanced Safety

Ergonomically designed jigs and fixtures improve operator safety by reducing the risk of injury and fatigue. This creates a safer working environment and can lead to higher job satisfaction and productivity.

Advanced Techniques in Jig and Fixture Design

To further enhance the efficiency and quality of manufacturing processes, several advanced techniques can be integrated into jig and fixture design:

1. Modular Design

Modular jigs and fixtures are composed of interchangeable components that can be easily reconfigured for different tasks. This flexibility allows for quick adaptation to changing production needs, reducing setup times and costs.

2. Automation Integration

Integrating jigs and fixtures with automated systems can significantly enhance efficiency. Automated loading and unloading, as well as the use of robotic arms for positioning workpieces, can streamline processes and reduce manual labor.

3. Computer-Aided Design (CAD)

Utilizing CAD software in the design process allows for precise modeling and simulation of jigs and fixtures. This enables designers to test and optimize designs virtually, reducing the need for physical prototypes and speeding up the development process.

Partnering with AscendTech for Optimal Jig and Fixture Solutions

Implementing the essential design principles of jigs and fixtures is crucial for improving manufacturing efficiency and quality. By focusing on accuracy, simplicity, robustness, interchangeability, ergonomics, and ease of maintenance, businesses can enhance their production processes and achieve consistent, high-quality results.

Partnering with a trusted provider like AscendTech ensures access to expert knowledge, advanced design techniques, and state-of-the-art equipment. AscendTech offers customized solutions tailored to specific manufacturing needs, helping businesses stay competitive in an ever-evolving industry. With AscendTech's support, manufacturers can optimize their jig and fixture designs, streamline operations, and achieve new levels of efficiency and quality.

Explore AscendTech's comprehensive range of products and engineering services to discover how they can help you achieve manufacturing excellence.

How can we help you?

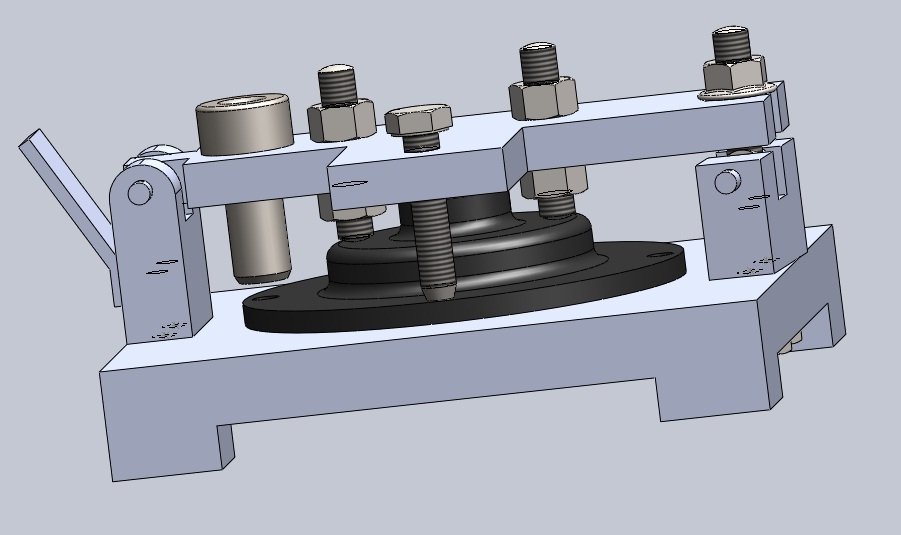

Interested in our vibration testing fixture design?

Send us your inquiry via the Fixture Design Form and we will be pleased to help you.