What Factors Affect the Severity of the Drop Testing?

The severity of the drop testing can be affected by a variety of factors, including the height of the fall, the surface on which the object lands, and the shape and composition of the object.

Height is perhaps the most important factor in determining how severe a drop will be. The higher an object falls, the more force it will experience upon impact. This force can cause extensive damage to an object, depending on its composition and shape.

The surface on which an object lands is also important. Hard surfaces, such as concrete or asphalt, can cause significant damage upon impact. Objects that land on softer surfaces, such as grass or sand, may not experience as much damage. However, it is important to note that even soft surfaces can cause injuries if an object falls from a high enough height.

Shape and composition are two additional factors that affect severity. Objects with sharp edges or points are more likely to suffer damage than those that are smooth and round. Additionally, objects made of sturdy materials are less likely to break than those made of weaker materials.

DROP SURFACE HARDNESS

The drop surface material hardness influences the severity of drop testing.

Harder Surfaces

generally, increase the severity of the test because they absorb less energy than softer surfaces during an impact. Some of a product’s kinetic energy (energy from its motion) is transferred from the product to the surface it impacts.

Softer Surfaces

generally, decrease the severity of the test because they absorb more energy than harder surfaces by increasing the impact time. Since the change in momentum to bring a falling object to a stop is fixed, impact force must decrease as impact time increases. Therefore, softer surface materials have lower impact forces than harder surface materials.

For example, several different drop surfaces, in order of increasing hardness, include:

Plywood

Vinyl tile placed over concrete

Concrete

Steel

A drop test to vinyl tile is less likely to see failures than a drop test to concrete since vinyl tile is a softer material than concrete. In contrast, while concrete is not as hard as steel, its rough surface leads to several localized high impacts, and thus a more severe drop.

Note: All surfaces are thick enough to resist any bending during impacts. MIL-STD requires a surface thickness of 2 inches.

DROP SURFACE ROUGHNESS

The roughness of a surface also influences the severity of drop testing.

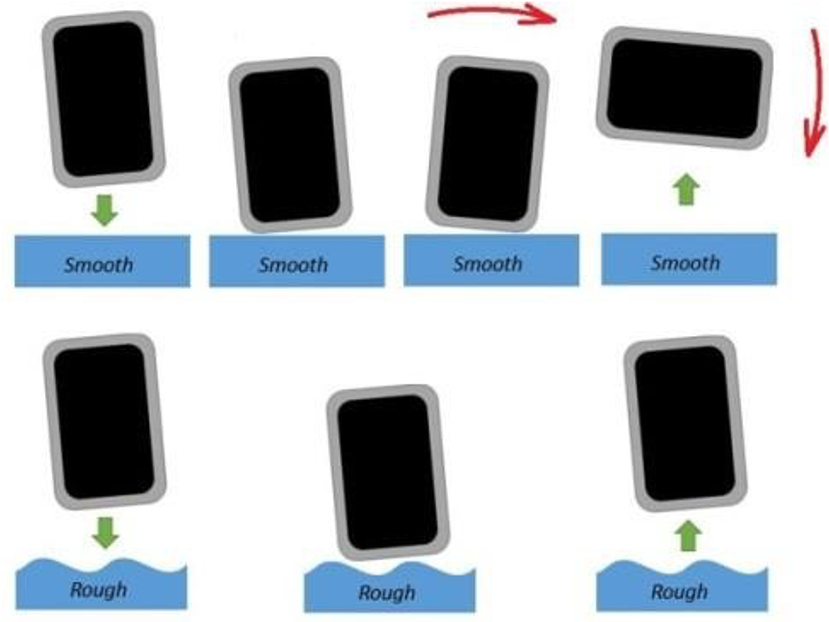

Smoother Surfaces have fewer bumps (localized impacts) on them and are less likely to cause damage to the test unit.

Rougher Surfaces cause higher impacts during drop testing because:

The bumps on the surface act like point contacts and concentrate loads on the test unit during drops

The rough surface tends to grip into the test subject’s housing, thus preventing sliding of the unit that would otherwise release impact energy through rotational motion.

For example, drops to concrete are generally more severe than drops to steel for a given height because concrete is much rougher than steel. As a result, drops to concrete are more likely to produce failures, such as broken displays and product scarring, than are drops to steel. However, specification sheets can specify a polished concrete drop surface, which is less likely to grip the product, generally leaving less scarring and resulting in more energy being transferred to rotational motion rather than having to be absorbed by the product.

Accelerometer Testing

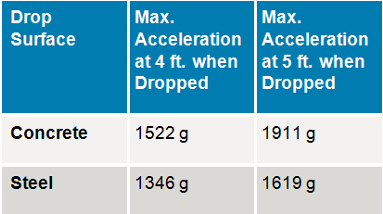

The following table presents an example of test data for a specific case, which changes only the drop surface and height.

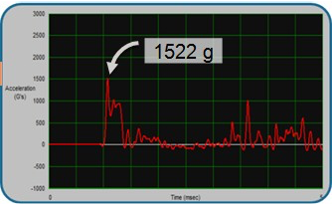

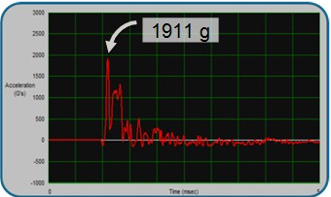

The following figures illustrate the acceleration data above when the device is dropped to concrete only (single surface).

Figure 1: 4 ft. Drop to Concrete

Figure 2: 5 ft. Drop to Concrete

Data from dropping the same device to various surfaces and heights reflects the expected trends in acceleration. For a single surface material, acceleration upon impact increases with increasing drop height because an object dropped at a higher height has more time to gain speed before hitting the ground. As a result, it takes a greater impact acceleration to slow down and stop the object’s motion.

Not all drop surfaces have the same effect on products

Determine the drop standards (MIL-STD810G) or specification references that can be used

When assessing drop performance, one should look at different drop surfaces. For example:

Concrete

Polished concrete

Steel

2 inches plywood over concrete

Vinyl tile over concrete

Do you need to perform a drop test? Contact our lab

Credit: Various Sources