What Is The Use Of Vibration Testing Equipment?

Vibration testing equipment is commonly used in a variety of industries to test the durability of products and components. By subjecting items to vibration, manufacturers can ensure that they will withstand the rigors of use in the real world. This type of testing can be used on everything from electronics to vehicles.

What is the use of vibration testing equipment?

Vibration testing equipment is used to test the response of materials and structures to vibration. It is an essential tool for engineers to understand the behavior of materials and structures under vibrational loading. Vibration testing equipment can be used to test a wide range of materials, including metals, plastics, composites, and even human tissue.

What are the benefits of using vibration testing equipment?

Vibration testing equipment can be used to test a variety of products and materials. By exposing the material or product to different frequencies of vibration, you can learn about its characteristics and how it will perform under various conditions. Additionally, vibrating testing equipment is often used to find potential problems with products before they are used by consumers. This can help to ensure that products are safe and durable before they reach the market.

How does vibration testing equipment work?

Vibration testing equipment is used to simulate the conditions that a product will experience during use. By subjecting the product to vibration, manufacturers can test for potential problems and identify areas that need improvement.

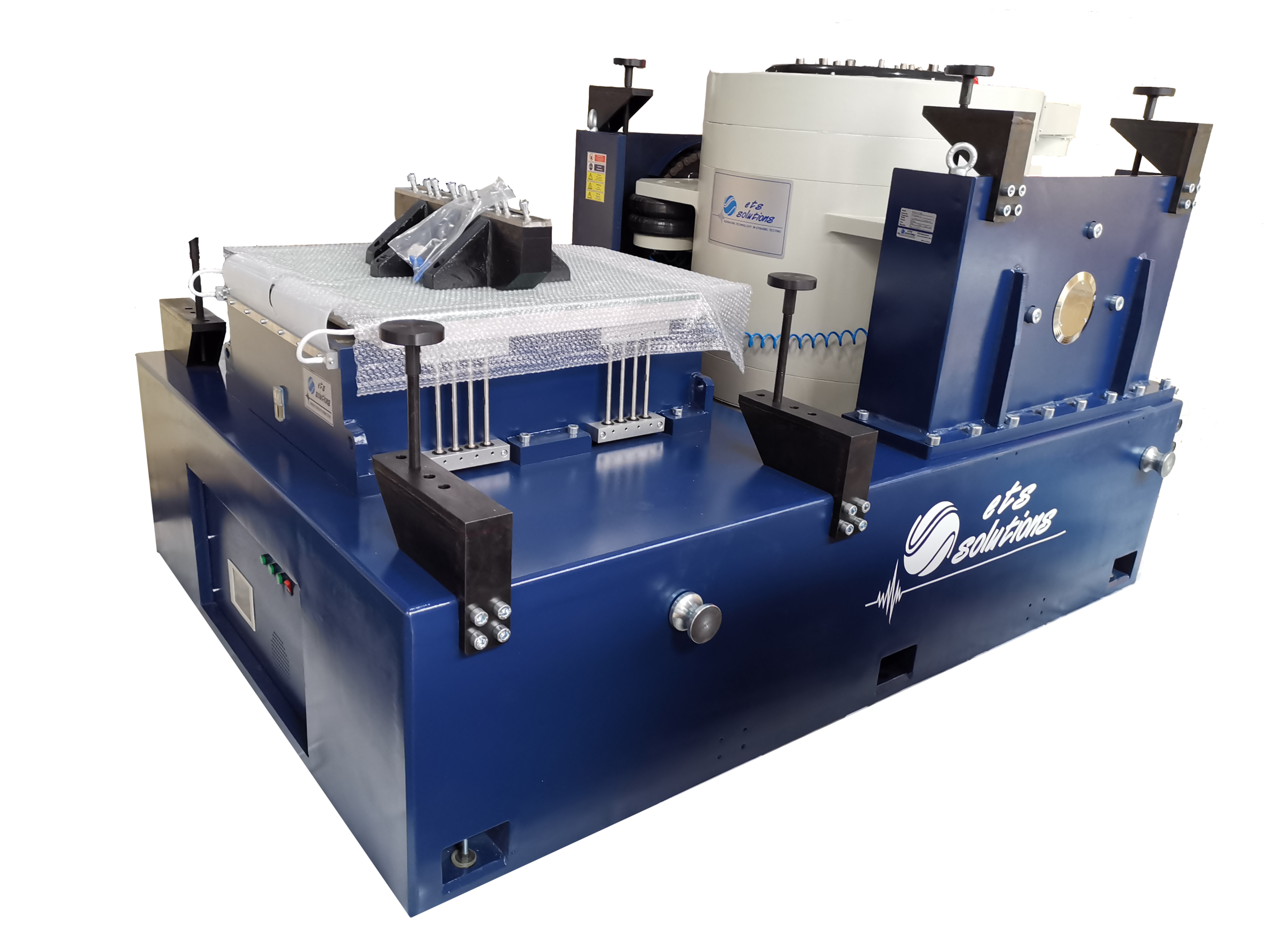

Vibration testing equipment usually consists of a shaking table or platform that is mounted on a frame. The frame is then connected to a vibration source, such as an electrodynamic shaker. The product under test is placed on the table or platform, and the shaker produces vibrations that cause the table or platform to move.

The amplitude, frequency, and duration of the vibrations can be varied to simulate different types of conditions that the product may experience in use. For example, high amplitude, low-frequency vibrations can simulate transportation conditions, while low amplitude, high-frequency vibrations can simulate operational conditions.

Vibration testing is an important tool for ensuring the quality and safety of products. By simulating real-world conditions, manufacturers can identify potential problems early on and make necessary improvements before the product goes to market.

AscendTech and VR Workshop:

Fundamentals of Shock Response Spectrum (SRS) - the most prominent tool for complex shock testing.

AscendTech and VR Workshop: Fundamentals of Shock Response Spectrum (SRS) - the most prominent tool for complex shock testing.

What are the different types of vibration testing equipment?

There are many different types of vibration testing equipment available on the market. Each type of equipment has its own unique set of features and benefits. Here is a brief overview of some of the most popular types of vibration testing equipment:

Vibration Tables: Vibration tables are commonly used to test the durability of products and packaging. They can also be used to simulate real-world conditions, such as transportation vibrations.

Vibration Chambers: Vibration chambers are enclosed chambers that subject products to controlled levels of vibration. This type of testing is often used to assess product reliability under extreme conditions.

Shock Testers: Shock testers are used to test the resistance of products to sudden impact or shocks. This type of testing is important for assessing the safety of products that may be subject to sudden impact in the real world, such as during the transportation.

Environmental Chambers: Environmental chambers can be used for a variety of purposes, including simulating different types of climates or storage conditions. This type of testing is important for assessing the long-term performance of products in different environments.

Drop Testers: Drop testers are used to assess the resistance of productsto impact when dropped from a certain height. This type of testing is important for assessing the safety of products that may be subject to dropping in the real world, such as during transportation.

Torsion Testers: Torsion testers are used to assess the resistance of products to twisting or torque. This type of testing is important for assessing the strength and durability of products that may be subject to twisting or torque in the real world, such as during transportation.

Cyclic Fatigue Testers: Cyclic fatigue testers subject products to repeated cycles of loading and unloading. This type of testing is important for assessing the long-term performance of products that may be subject to repeated cycling in the real world, such as during transportation.

Thermal Shock Testers: Thermal shock testers subject products to sudden changes in temperature. This type of testing is important for assessing the resistance of products to thermal shock in the real world, such as during transportation.

How to choose the right vibration testing equipment?

There are many different types of vibration testing equipment on the market, so how do you know which one is right for your needs? Here are a few factors to consider when choosing vibration testing equipment:

The type of material you will be testing. Different materials require different types of testing, so make sure the equipment you choose is designed for the material you are testing.

The size of the sample. Some vibration testing equipment is only designed for small samples, while others can accommodate larger samples. Make sure the equipment you choose can handle the size of sample you need to test.

The frequency range you need. Different materials require different frequency ranges for testing, so make sure the equipment you choose can generate the frequencies you need.

The level of precision you require. If you need very precise results, make sure the equipment you choose is capable of providing them.

Your budget. Vibration testing equipment can vary widely in price, so it's important to set a budget before shopping and stick to it.

By keeping these factors in mind, you can narrow down your choices and find the right vibration testing equipment for your needs.

Conclusion

Vibration testing equipment is used to test products for durability and reliability. By simulating the conditions that a product will be subjected to in its lifetime, manufacturers can ensure that their products are up to the task of withstanding real-world use. This type of testing is essential for ensuring the safety and quality of products, and it helps to catch any potential problems before they become expensive or dangerous failures.