Shock Testing

Shock testing is a critical process used across various industries to evaluate the resilience and reliability of products subjected to dynamic mechanical forces. This comprehensive guide explores the fundamentals of shock testing, emphasizing the significance of classical shock pulses, the types of shock testing machines, and the key steps involved in conducting shock tests on electrodynamic shakers.

Shock Response Spectrum Analysis Approach for Optimal Design of Electronic Devices

The Shock Response Spectrum (SRS) is a vital tool in the design of electronic devices. It provides engineers with a graphical representation of the device's response to shock loads, helping them optimize its shock resistance. By analyzing the SRS curve, engineers can identify critical frequencies, make informed design decisions, and improve reliability. The SRS analysis ensures cost-effective design, reduces the risk of failure during shocks, and enhances overall device performance.

Understanding the Importance of Mechanical Testing in Transportation Simulation

The transportation of goods can be a stressful process for businesses, as the products are often subjected to a variety of shocks and vibrations that can damage them during transit. To ensure that products arrive at their destination undamaged, businesses need a reliable and effective solution for mechanical testing in transportation simulation. AscendTech Group's TS Transportation Simulation Test System provides just that - by simulating actual road conditions, our solution evaluates the effect of working conditions on products, packaging, and internal structure of goods. With our testing system, businesses can optimize their transportation processes and protect their products from transportation stresses and strains.

Mechanical Shock Testing Introduction

In the world of mechanics, precision is key. Before products and designs can go out into the world, engineers need to understand every possible facet of their work. How strong is it? How fast, flexible, and durable is it? The answer is to create tests that mimic potential conditions the design might face, to evaluate how well the design performs against them. One such test is one that we call mechanical shock testing. This test is critical to the safety of many different types of mechanical designs.

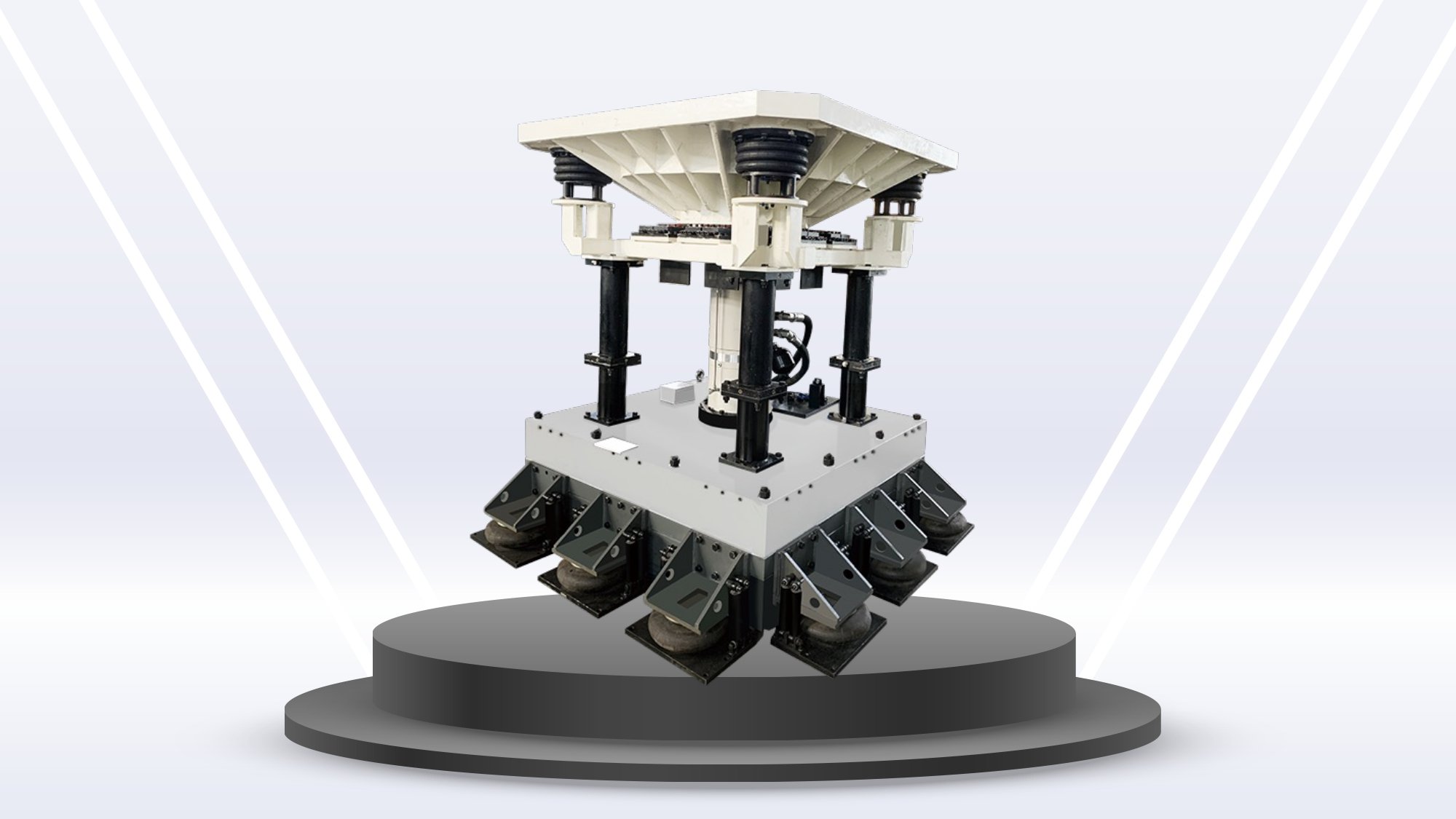

What Is a Hydraulic Vibration Shaker Used For?

Vibration shakers are versatile tools that can be used for a variety of purposes. Hydraulic vibration shakers are particularly useful for simulating real-world conditions and testing products under extreme conditions. If you're looking for a way to test your products under the most realistic conditions possible, a hydraulic vibration shaker is an excellent option to consider.