Drop Test System

Drop test is performed to determine the ability of a package to endure the impacts occur in the process of transportation. During the products handling or transport process, drop or fall often happens, which results in damage within the products. Drop Test Machine simulates the drop/ fall of carton or finished product, which enable the researcher to assess the damage occur in any accidental fall. Drop test can be performed to all the angles and faces of the products in accordance to international standards.

ZDD Zero-distance

Drop Test System

-

ZDD series drop tester, mainly simulates the resistance to drop and impact of large and heavy packaging products. Its strong power system and unique sample holder facilitate easy loading and unloading of oversized and overweight items and automatically rise to the setting. After the height, the drop test is completed. It can realize the drop test of the edge, surface and angle of the sample. This equipment is mainly used to evaluate the ability of product or packaging to withstand drops during transportation and loading and unloading, so as to improve product and packaging design.

Driven by pneumatic and servo motors, stable lifting process with upper and lower displacement restrictions, safe and reliable.

Adopt single-track lifting method, and the height can be adjusted arbitrarily.

It can clamp and drop the test specimen in different directions such as edges, faces and angles.

The testing machine adopts PLC full-automatic control, large size true color touch LCD screen.

No special foundation required, no other complicated operation or installation.

Remote control can be realized to ensure the safety of operators (customized functions).

-

ISO2248-1985(E)

IEC68-2-27 ISTA

SD Small

Drop Test System

-

SD series small drop tester is suitable for free-fall test of small consumer electronics and components such as mobile phones, walkie-talkies, electronic dictionaries, CD / MD / MP3 and so on, applicable standards JISC 0044 and IEC 60068-2-32. Through standard tests on electronic products (surface drop, corner drop, edge drop, etc.) and collecting data, it simulates the vertical drop impact of electronic products during transportation and handling. It provides a basis for the design of the product's buffer and vibration damping and the selection of structural materials.

It can be dropped naked or dropped with packaging to evaluate the impact resistance or the damage caused by the fall of the product during transportation. It is an indispensable test method to improve the product's quality. It is applicable for electronic product research, development, quality control, manufacturing and other links.

Upper and lower displacement limit to guarantee safe.

The lifting height can be adjusted arbitrarily to meet the different requirements.

It can clamp and drop the test sample at any angle

Just place the machine on a flat marble or concrete floor, no special foundation needed

Hand-held pad human-computer interaction software, easy to operate

The drop height is adjustable and the control is accurate up to 2mm

No special foundation required, no other complicated operation or installation

-

ISO2248-1985(E)

IEC68-2-27 ISTA

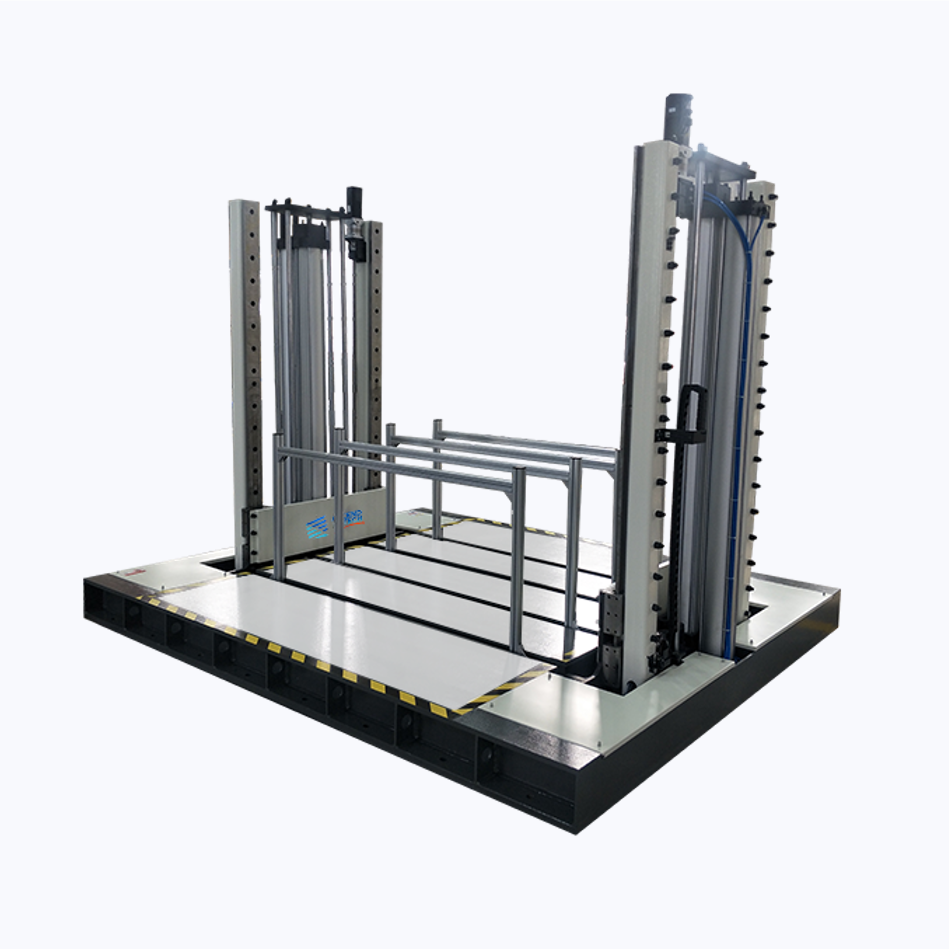

DLZDD Double Lift Zero-distance

Drop Test System

-

DLZDD series double lift zero drop tester is mainly suitable for large size packaging products to resist drop impact performance, its powerful power system and unique sample support for easy loading and unloading of oversized, overweight items, and automatically rise to the set height, complete the drop test.

Driven by pneumatic and servo motors, stable lifting process with upper and lower displacement restrictions, safe and reliable.

Adopt dual-track lifting method, and the height can be adjusted arbitrarily.

It can clamp and drop the test specimen in different directions such as edges, faces and angles.

The testing machine adopts PLC full-automatic control, large size true color touch LCD screen.

No special foundation required, no other complicated operation or installation.

Remote control can be realized to ensure the safety of operators (customized functions).

-

ISO2248-1985(E)

IEC68-2-27 ISTA