Vibration Sensor: Definitions, Applications and How to Use it

What is a vibration sensor?

The first ones appeared in the early 1900's and were large mechanical devices, devised to measure and to record tractive and brake effort in the automotive industry. They consisted of two tracing pens, one centred and one pendulum mounted, above a paper scroll. The scroll was housed on two clockwork driven drums operated by a winding handle. Before its invention, the only method of measuring acceleration was by observation.

Modern day vibration sensors are electronic devices, using either piezoelectric or piezoresistive technology. Most models used in plant monitoring applications are the piezoelectric types.

A vibration sensor is a device that measures the amount and frequency of vibration in a given system, machine, or piece of equipment. Vibration sensors can be used to give maintenance teams insight into conditions within key assets that might lead to equipment failure, allowing them to predict the maintenance of the machinery, to reduce overall costs and increase the performance of the machinery.

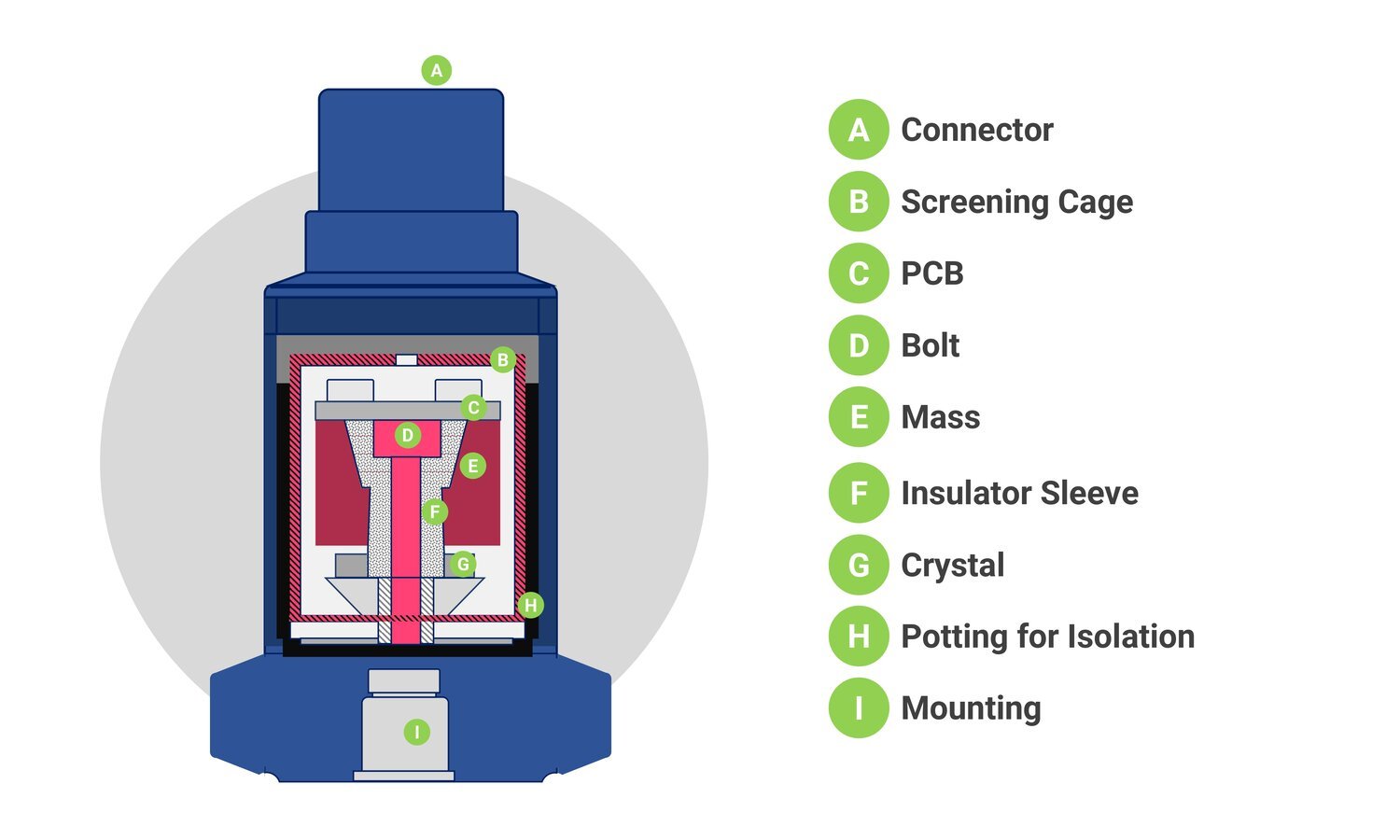

Their construction consists of a crystal of piezoelectric material to which is attached a seismic mass. When the crystal is stressed in tension or compression, it generates an electrical charge which is proportional to the acceleration level it is experiencing. Internal circuitry converts this signal into a voltage or current (4-20mA) output for data collectors or process control loops. (see figure 1)

figure 1

This robust device has no moving parts and offers long term stability and reliability. It has very wide frequency and dynamic ranges and signals can be integrated to give velocity and displacement values.

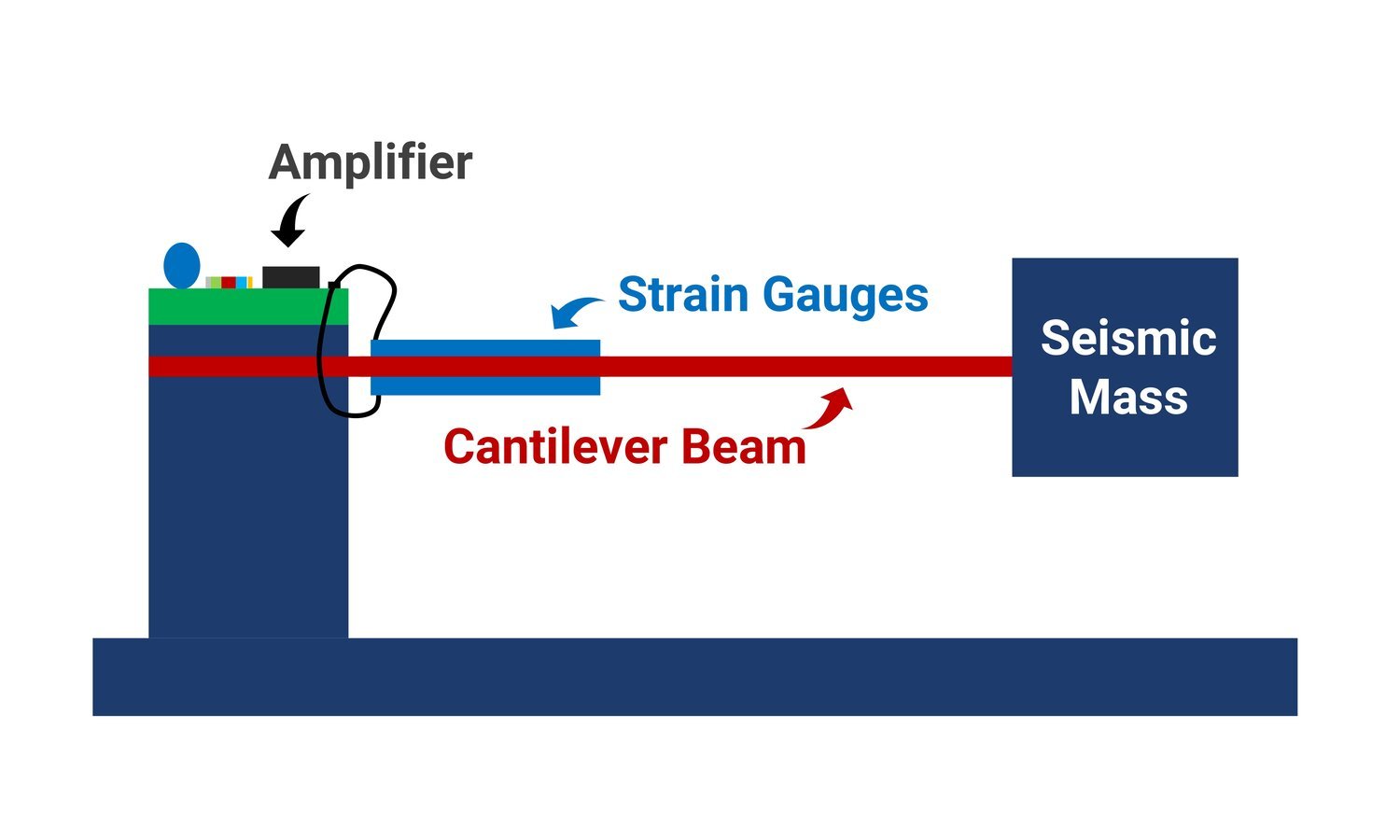

Piezoresistive accelerometers consist of a seismic mass which is attached to a cantilever beam. The beam is deflected whilst experiencing 'g' forces and this movement is converted to an electrical signal by resistance changes in a semiconductor sensing element. Internal electronic circuitry provides amplification of the signal and temperature compensation.

The frequency range of this device is lower than piezoelectric versions, but has the advantage of being able to monitor static or DC acceleration levels.

Over the last twenty five years, different versions of vibration sensors have been designed to suit a whole new range of environmental conditions in an ever increasing need to perform consistently in differing industrial applications. These conditions have helped to create models which are primarily robust with an outer stainless steel construction. They will operate successfully in both high and low temperatures, typically over -55 to +140 degrees C. The stainless steel housing is welded to give protective sealing to IP68, or full liquid submersion in underwater applications. Radiation resistant versions are available, as are fully ATEX approved intrinsically safe models for operation in potentially explosive atmospheres. Cable choice for the different applications covers tough stainless steel braiding, submersible and high temperature PTFE options. Mechanical fittings are also important for the correct fixing of the sensor to ensure correct transfer of the vibration signal and come in a choice of differing threads, adaptors, quick-fit or glue mounting studs and magnets. Custom designed versions are also available, where a special sensor is created to exactly suit the conditions it will need to operate under.

Which industries use the vibration sensor the most?

Below is a list of the most common industrial sectors that employ vibration sensors to monitor the vibrations:

Aerospace

Automotive & Transportation

Pulp and Paper

Food and Beverage

Oil and Gas, Refining, Petrochemicals

Power Generation (fossil fuel, nuclear, hydro, wind turbines)

Machine tools

Metalworking

Mining, Mineral Processing, and Cement

The most common industrial applications of vibration sensors include rotating equipment such as pumps, motors, fans, compressors, gearboxes, gas turbines, bearings on conveyor systems, wind turbine gearboxes, wind turbine generators, dryer sections (pulp & paper), ovens & kilns (mineral processing), and hot rolling mills (metalworking).

More and more industries are becoming aware of the importance of vibration condition monitoring of their process or production plant.

In recent years, the global automotive industry has witnessed strong growth and profitability. The increased demand for automobiles has also encouraged automobile manufacturers to monitor the health of their plant machinery effectively to keep the production line in operating condition. Moreover, condition monitoring has become crucial for maintaining the quality of products and the stability of manufacturing processes. With the help of vibration monitoring equipment and vibration sensors, automobile manufacturing plant managers can ensure the proper functioning of automated machines, metalworking equipment, and robotics, thus ensuring the smooth flow of different production processes.

The water industry now monitors its many water processing pumps from those situated in remote pumping stations to those in large scale sophisticated water treatment and de-salination sites.

The food processing industry needs to monitors its many rotating machinery parts in vibratory conveyor systems, cooling fans, food pumps and mixers, the chip, can cause cost losses of many thousands of dollars.

Building services is another massive area where the performance of motors, pumps and fans is critical in public buildings such as hospitals, airports, railway stations, office blocks, hotels, etc.

Vibration sensors play a vital role in the oil and gas industry by ensuring that the production machinery is operational and the downtime is minimized, thereby leading to a reduction in operating costs and an increase in productivity and monetary gains. These sensors help reduce unplanned outages and optimize machine performance. This, in turn, helps in reducing maintenance and repair costs. Vibration sensors designed for monitoring applications are used to monitor motors, critical pumps, fans, gearboxes, and compressors in the oil and gas industry.

The deterioration in the condition of machines used in chemical plants and their performance is usually associated with vibration, misalignment, and imbalances in moving parts; and poorly lubricated parts. Detecting these underlying problems at an early stage allows the rectification of issues before they affect different processes, thus optimizing the performance of chemical plants. Vibration monitoring equipment and tools are used in the chemicals industry to detect vibration-related issues. These tools help improve the maintenance effectiveness, increase profitability, provide safety warnings, and reduce operating costs of chemical plants. In a general chemical processing plant, vibration sensors with a minimum of 10–10,000 Hz frequencies are required for the effective monitoring of turbines, blades, and gears.

The power industry is facing challenges owing to the continuously increasing demand for power and the requirement to reduce distribution losses. This has led power generation companies to offer continuous power supply at low costs and monitor their processes for any unwanted changes. Hence, vibration sensors play a crucial role in the power sector. Vibration sensors help in tracking rotor imbalances, aerodynamic asymmetry, surface roughness, and overall performance, as well as carry out offline and online measurements of stress and strain in energy and power industry.

Another topical area where vibration sensors are being used is with the latest construction of new wind power farms where the rotor of the blades need to be supervised for optimum and continuous performance.

In fact, everywhere you look rotation in bearings, whether rotary or linear is taking place and is potentially a vibration monitoring point.

The sensor technology has been advancing at a rapid rate. The use of advanced sensors such as wireless sensors, fiber-optic sensors, and micro-electro-mechanical system (MEMS) sensors is increasing continuously across the world. Sensors that are resistant to extreme climatic conditions are largely deployed in monitoring applications. Numerous sensors are installed in the wireless sensor networks to offer accurate results.

How to use or work with a vibration sensor

Before taking a vibration measurement, you need to attach a sensor that can detect vibration behavior to the machine that is being measured. A vibration sensor either connects directly to an asset or monitors it wirelessly. Once placed, it will detect vibrations from the asset through various means, depending on the type of sensor.

When determining the correct vibration sensor for your application it is important to consider:

The range and accuracy

Environment conditions

The shape of the measuring surface

So that the sensor will perform the best in your application.

Various types of vibration sensors are available, but a type called accelerometer is normally used as it offers advantages over other sensors. An accelerometer is a sensor that produces an electrical signal that is proportional to the acceleration of the vibrating component to which the accelerometer is attached.

What is the acceleration of a vibrating component? It is a measure of how quickly the velocity of the component is changing.

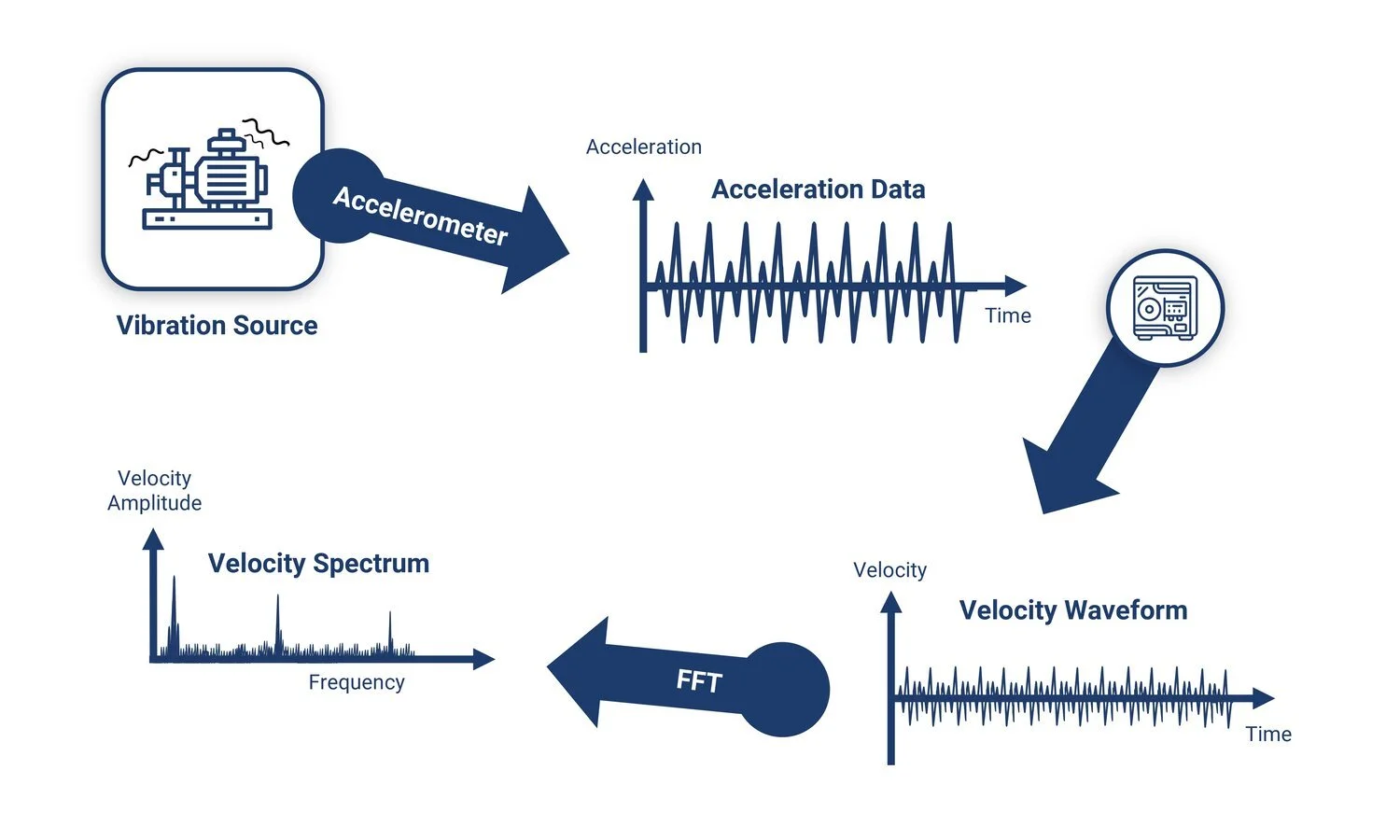

The acceleration signal produced by the accelerometer is passed on to the instrument that in turn converts the signal to a velocity signal. Depending on the user's choice, the signal can be displayed as either a velocity waveform or a velocity spectrum. A velocity spectrum is derived from a velocity waveform by means of a mathematical calculation known as the Fast Fourier Transform or FFT.

The diagram below is a very simplistic explanation of how vibration data is acquired.

How is the Accelerometer Mounted?

Most machines involve rotary mechanisms. Motors, pumps, compressors, fans, belt conveyors, gearboxes, all involve rotary mechanisms and are frequently used in machines.

Most rotary mechanisms in turn have bearings that support the weight of rotating parts and bear the forces associated with rotary motion and vibration. In general, large amounts of force are borne by bearings. It is not surprising that bearings are often the place where damage occurs and where symptoms first develop.

Vibration measurements are thus usually taken at the bearings of machines, with accelerometers mounted at or near the bearings.

Since conclusions regarding machine condition - and hence whether or not money and human safety are risked - depend on the accuracy of measurements, we must be very careful how measurements are taken. It is important to always remember that the way in which we mount the accelerometer very much determines the accuracy of measurements.

How should accelerometers be mounted to ensure measurements are accurate and how can we do so safely? Here are some guidelines:

Mount as close as possible to the bearing

Make sure the accelerometer is firmly attached

Make sure the accelerometer is oriented correctly

Mount the same accelerometer in the same location

Mount the accelerometer on something substantial

Take care of the accelerometer

Take care of personal safety

Why you need to monitor vibrations?

Any business that uses heavy equipment in their daily operations can benefit from monitoring vibrations. The advantages of doing so include the following:

Understand causes of damage

Monitor repair needs

Keep an overall health check on equipment

Vibration sensors are an excellent way to monitor the health of key assets. They provide precise information on how individual pieces of equipment are doing, and the data they provide can help you anticipate when future maintenance needs may occur. The end result is a more streamlined maintenance process and improved machine health.

During the pandemic, critical industries such as energy and power, chemicals, food and beverages, and healthcare continue to witness an increased demand for vibration sensors to ensure safe and efficient operations of machinery. Currently, online vibration monitoring is a preferred monitoring process as it is more advanced than portable condition monitoring and provides real-time machine data to plant operators.