Do We Need To Calibrate Our Vibration Controller Unit?

To run a vibration testing, we need to set our test specification (demand) at the vibration control software and let the vibration controller to control the rest. A feedback sensor will send feedback signal. And based on this feedback signal, vibration controller will adjust the drive signal to make the actual vibration signal aligned with the test specification.

Looking at how this system works, it is clear that the vibration controller is playing a very important part to accuracy of the vibration testing.

Photo credit: Vibration Research

What is actually needed to verify during calibration of vibration controller?

For accelerometer, the output of calibration process will be the sensitivity values of the accelerometer across certain frequency range or calibration points.

Unlike accelerometer calibration, the calibration process of a vibration controller is generally to verify the accuracy of the all input and output channels of the vibration controller.

Some of manufacturers develop their own calibration process.

This verification/calibration process generally may cover following aspects:

1. Verification of Output Channel Values

Most of vibration controllers have two output channels. One is the main/primary output channel which is connected to the amplifier of the vibration testing system. This output channel is the one sending drive voltage to be amplified by the amplifier and forwarded to the armature coil of the vibration testing system. Other than the main/primary output channel, most of the vibration controllers have another one output channel called auxiliary/secondary channel (some manufacturers call it "COLA" channel). Some manufacturers allow the user to use this auxiliary channel to drive another vibration shaker simultaneously, by purchasing additional software license.

In order to run verification on both Output Channel values, some manufacturers use relatively simple verification procedure by using only single calibration point, then verify the zero offset and the root mean square (rms) values. Some other manufacturers use more complicated procedure involving many calibration points across calibration frequency range. Other the output values, some manufacturers also include frequency verification in their verification/calibration procedure.

2. Verification of Input Channel Values

The complexity and duration of Input Channel verification/calibration is depending on below factors:

Channel/Sensor Mode

Number of Channels

Calibration Points

Most of vibration controllers are able to accept voltage sensor and IEPE sensor. Few of vibration controllers are able to accept charge accelerometer.

The calibration/verification for the input channel of vibration calibration will need to be performed separately to all channel/sensor mode (voltage, IEPE, charge, etc). This means, the more type of sensors that vibration controller can accept, the verification/calibration procedure may become more complicated and take longer duration.

When calibration/verification can be performed at all input channels simultaneously, then number of channels will not really influence the duration of the calibration.

But in few cases, when the controller has special channel/sensor mode, and it needs special device to calibrate/verify each channel, then the verification may take even longer duration.

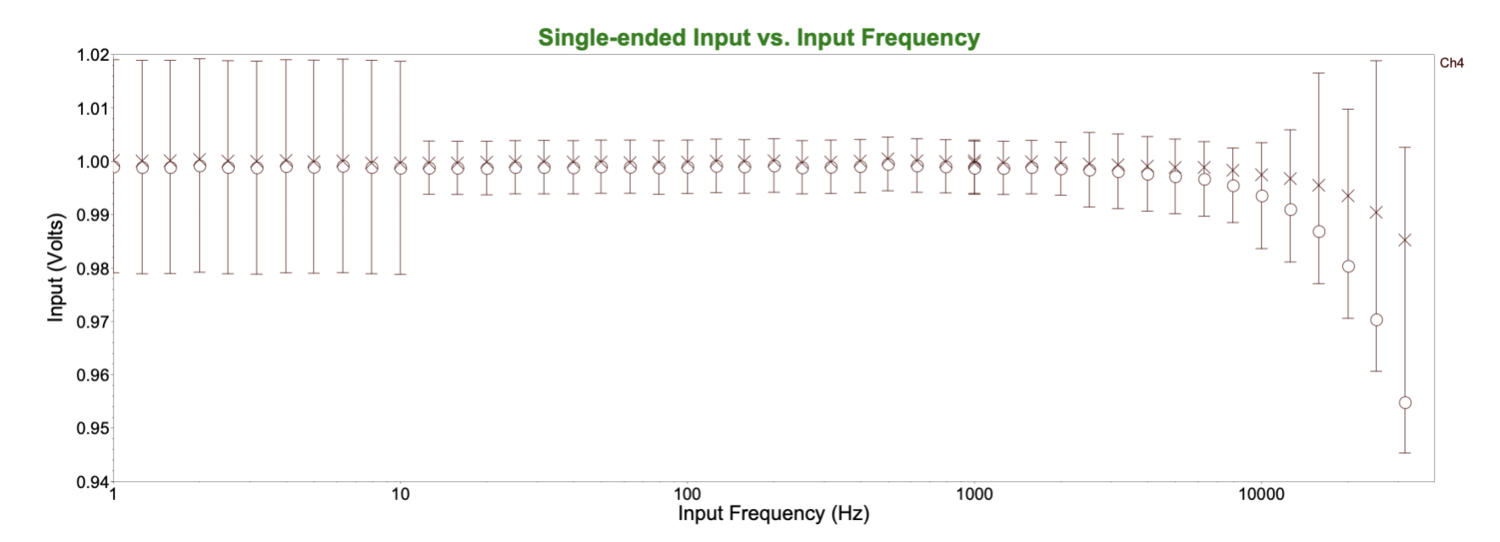

Like the verification of Output Channel values, the verification of Input Channel is also influenced by calibration points. Some manufacturers use only single calibration point, while other manufacturers use more calibration points across calibration frequency range. But for verification of Input Channel, some manufacturers also use sample rate as variable factor.

Calibration/Verification Procedure

For Vibration Controller calibration, commonly a calibrated digital multi meter will be used as reference standard. This digital multi meter will be connected to output and input channels of the vibration controller, and the reading at the software will be compared to the reading at digital multi meter. The reading at the multi meter may need to be recorded manually or recorded automatically by the software.

Generally, there are three common calibration procedure used by for Vibration Controller:

To calibrate initially the Output Channels by using the digital multi meter as reference standard. After that, to calibrate the Input Channels by using an Output Channel as reference.

To calibrate initially the Input Channels by using the digital multi meter as reference standard. After that, to calibrate the Output Channels by using an Input Channel as reference.

To calibrate both Output and Input Channels by using the digital multi meter as reference standard.

Do you need Vibration Controller or need to calibrate your vibration controller?

Our Lab is ISO17025 SAC-SINGLAS Certified.

Schedule your appointment today.

How Can We Help You?

Interested in our Testing & Calibration services? Send us your inquiry via the Testing & Calibration Lab Form and we will be pleased to help you.