Shock Testing

Shock testing is a crucial component of vibration testing, playing a pivotal role in evaluating the resilience and reliability of various products subjected to dynamic mechanical forces. This article provides an in-depth exploration of the fundamentals of shock testing within the context of vibration testing. It offers insights into the significance of shock testing, its real-world applications, and its importance in ensuring product quality and safety.

Shock Testing

Shock testing is an essential aspect of vibration testing that seeks to mimic real-world scenarios where products are exposed to sudden and intense mechanical forces. It forms a critical part of product development and quality assurance in industries such as aerospace, automotive, electronics, and military applications. This section introduces the concept of shock testing and highlights its relevance in assessing the durability and functionality of products subjected to dynamic forces.

Significance of Shock Testing

Shock testing is employed to verify whether a product can withstand the mechanical stresses it might encounter during transportation, usage, or unforeseen events. It serves as a means to identify design weaknesses, potential failures, and areas for improvement. By subjecting products to controlled shocks, engineers and researchers gain valuable insights into their performance under extreme conditions, ultimately leading to enhanced product reliability and safety.

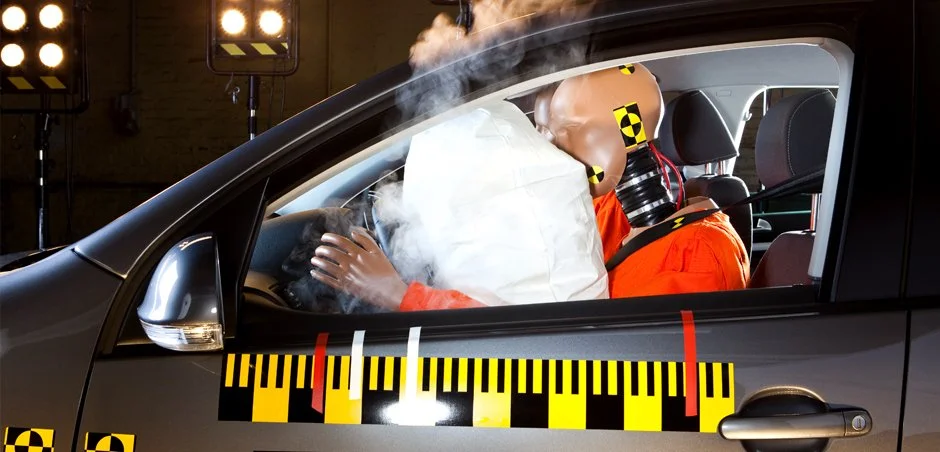

Real-world Example: Automotive Crash Testing

A compelling real-world example of the importance of shock testing is found in the automotive industry. Crash testing is a form of shock testing that evaluates the structural integrity and safety of vehicles during collisions. Researchers conduct controlled crash tests by simulating impacts, such as frontal collisions, side impacts, and rear-end collisions, to assess how vehicles and their occupants would fare in accidents.

These tests involve subjecting vehicles to precise shock pulses that replicate the forces generated during actual accidents. Advanced instrumentation, including accelerometers and high-speed cameras, capture data related to the vehicle's acceleration, deformation, and occupant safety. This data is then meticulously analyzed to improve vehicle designs, enhance safety features, and ensure compliance with industry safety standards.

An In-depth Look into Classical Shock Pulses

Classical shock pulses are characterized by their distinct waveform, which comprises a sudden, high-amplitude force followed by a rapid return to baseline. These pulses are carefully designed to mimic the abrupt impacts and shocks that products may experience during transportation, usage, or unforeseen events. Understanding the essential characteristics of classical shock pulses is crucial for conducting effective and relevant shock tests.

Duration

The duration of a classical shock pulse is typically short, reflecting the brief and intense nature of real-world shocks. This short duration allows for the evaluation of a product's response to sudden impacts. Longer durations may not accurately represent the forces products are designed to withstand.

Amplitude

Classical shock pulses are characterized by high amplitudes. The peak force is a key parameter that determines the intensity of the shock. The choice of amplitude depends on the specific application and the conditions a product is expected to endure. For instance, automotive crash tests require exceptionally high amplitudes to simulate the forces experienced during collisions.

Waveform

Several waveform shapes are employed in classical shock pulses, each with unique characteristics. Some common waveforms include:

1. Half-Sine Waveform

The half-sine waveform is perhaps the most widely used in shock testing. It features a rapid rise to peak force, followed by an equally swift return to baseline. This waveform is effective in simulating abrupt shocks and is commonly used in a variety of applications, including military and aerospace testing.

2. Sawtooth Waveform

The sawtooth waveform involves a gradual increase in force, followed by an abrupt drop to baseline. It is often used to replicate scenarios where products are gradually subjected to increasing stress levels, such as during acceleration in transportation or industrial processes.

3. Trapezoidal Waveform

Trapezoidal waveforms combine aspects of both half-sine and sawtooth waveforms. They feature a rapid rise to peak force, a plateau at the peak, and a sudden return to baseline. Trapezoidal waveforms are chosen when a test needs to simulate a shock with a specific force profile, such as in electronics testing.

Factors Influencing Pulse Selection

Selecting the appropriate classical shock pulse for a shock test is not arbitrary; it depends on various factors, including the application, industry standards, and the specific conditions the product is designed to endure. Here are some key considerations that influence pulse selection:

1. Industry Standards

Many industries have established standards for shock testing to ensure consistency and comparability of results. Adhering to these standards is crucial for product certification and compliance. For instance, the aerospace industry often follows standards set by organizations like ASTM and ISO.

2. Application

The nature of the application significantly impacts pulse selection. For example, automotive crash tests require high-amplitude, short-duration pulses to simulate collisions accurately, while consumer electronics testing may involve lower-amplitude, longer-duration pulses to mimic transportation shocks.

3. Environmental Conditions

The environmental conditions in which a product will operate also play a role in pulse selection. Products exposed to extreme environments, such as those used in arctic or desert conditions, may require shock tests that replicate the specific forces encountered in those environments.

4. Product Design

The design of the product itself influences pulse selection. Products with different structural characteristics and materials respond differently to shock. Therefore, the pulse chosen should be relevant to the product's design and intended use.

Types of Shock Testing Machines

There are various types of machines used for conducting shock tests, each with its own set of advantages and applications:

1. Mechanical Shock Test Machines

Mechanical shock test machines employ a purely mechanical system, such as a drop tower or a pendulum, to generate shock forces. These machines are particularly well-suited for testing larger and heavier test items, including automotive components and military equipment. The key advantages of mechanical shock test machines lie in their ability to produce highly controlled and repeatable shocks.

Real-world Example: In the automotive industry, mechanical shock test machines are extensively utilized to evaluate the durability and safety of vehicle components. For instance, airbag systems undergo rigorous testing using pendulum-based machines to ensure their reliability during accidents. These machines simulate the rapid deceleration forces experienced during a collision, allowing engineers to fine-tune airbag deployment mechanisms.

2. Electrodynamic Shakers

Electrodynamic shakers are prevalent in shock testing, especially within industries like aerospace and electronics. These machines generate shocks by rapidly accelerating a platform and then abruptly decelerating it to create the desired shock pulse. Electrodynamic shakers are prized for their precise control over shock parameters and their capability to replicate a wide range of shock profiles.

Real-world Example: Aerospace companies extensively use electrodynamic shakers to assess the structural integrity of aircraft components. For instance, the testing of aircraft landing gear involves subjecting the components to shock loads that simulate the forces experienced during hard landings. Electrodynamic shakers enable engineers to analyze the response of landing gear under such extreme conditions, leading to safer aviation systems.

3. Pneumatic Shock Test Machines

Pneumatic shock test machines rely on compressed air to generate controlled shocks. These machines are often employed for testing smaller and lighter components, including electronic devices. Their cost-effectiveness and ability to generate repeatable shock pulses make them a practical choice for a range of applications.

Real-world Example: In the electronics industry, pneumatic shock test machines are indispensable for assessing the durability of delicate components. For example, smartphones undergo pneumatic shock testing to ensure they can withstand the shocks and impacts associated with daily use. By subjecting devices to controlled shocks, manufacturers can identify potential weaknesses and make design improvements, ultimately enhancing product reliability.

Advantages and Applications

Each type of shock testing machine offers distinct advantages and finds applications in various industries:

Mechanical Shock Test Machines are preferred for their robustness and suitability for large and heavy items. They are commonly used in automotive, military, and industrial applications.

Electrodynamic Shakers excel in precision and versatility, making them ideal for aerospace, electronics, and vibration testing of sensitive equipment.

Pneumatic Shock Test Machines provide cost-effective solutions for testing smaller and lighter components, making them valuable in the electronics and consumer goods industries.

Running Shock Tests

Classical Shock Tests on Shakers

Classical shock tests are designed to simulate real-world scenarios where products experience sudden and intense mechanical forces. Electrodynamic shakers offer a controlled and repeatable environment for conducting such tests, making them a preferred choice in industries like aerospace, automotive, and electronics. To ensure accurate and reliable results, a well-structured testing process is crucial.

Step 1: Fixture and Mounting

The first step in conducting a classical shock test on an electrodynamic shaker is to securely attach the test item to the shaker platform using an appropriate fixture. The fixture should be carefully designed to replicate real-world conditions accurately. Considerations for fixture design include the material, size, and shape, as well as the attachment mechanism. A rigid and reliable fixture is essential to ensure that the test item remains in place during the test and that forces are accurately transmitted.

Real-world Example: In the aerospace industry, when testing aircraft components like landing gear, a fixture that simulates the attachment points and conditions during actual use is meticulously engineered. This ensures that the shock test closely mimics the forces experienced during landing and takeoff.

Step 2: Selection of Shock Parameters

Choosing the right shock parameters is critical to the success of a classical shock test. The selected parameters should align with the expected operating conditions of the product being tested. Key parameters include:

Amplitude: The peak force or acceleration of the shock pulse, which depends on the application. For instance, automotive crash tests require higher amplitudes to replicate the forces during collisions.

Duration: The time span over which the shock is applied. Short durations are typical for classical shock tests to simulate sudden impacts accurately.

Waveform: The shape of the shock pulse, such as half-sine, sawtooth, or trapezoidal. The choice of waveform depends on the specific application and the forces the product is expected to endure.

Step 3: Pre-test Inspection

Prior to conducting the shock test, perform a thorough pre-test inspection. This inspection involves assessing both the test item and the electrodynamic shaker system to ensure that everything is in proper working order. Check for any visible defects, loose connections, or anomalies that could affect the test's integrity.

Step 4: Test Execution

Once the fixture is securely mounted, shock parameters are selected, and the pre-test inspection is completed, initiate the shock test. Ensure that the electrodynamic shaker generates the specified shock pulse accurately. During the test, closely monitor the test item's response for any unexpected behavior or anomalies. This real-time observation allows for immediate adjustments or the termination of the test if safety concerns arise.

Real-world Example: In the automotive industry, during a frontal crash test, engineers closely monitor the vehicle's response to ensure that airbag deployment and structural integrity perform as expected. Any deviation from the desired behavior can lead to design modifications.

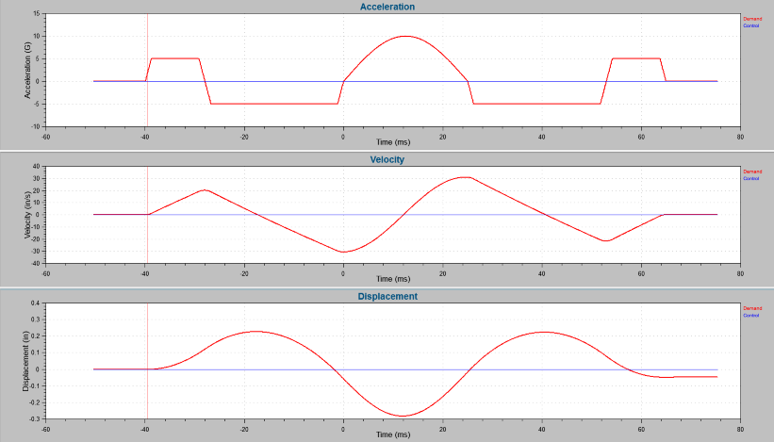

Step 5: Data Collection

Collecting data during the shock test is essential for subsequent analysis and validation. Utilize sensors and measurement equipment to capture relevant data, including acceleration, displacement, and strain. This data provides critical insights into how the test item responded to the shock, helping engineers assess its performance under extreme conditions.

Conducting classical shock tests on electrodynamic shakers is a meticulous process that requires careful planning and execution. The systematic approach outlined in this guide, encompassing fixture and mounting, shock parameter selection, pre-test inspection, test execution, and data collection, ensures that the test results are accurate, reliable, and aligned with the product's real-world requirements. By following these steps, engineers and researchers can effectively evaluate a product's ability to withstand sudden mechanical forces, ultimately contributing to enhanced product reliability and safety across various industries.

Classical Shock Testing Control and Analysis Techniques

Classical shock testing is a critical phase in assessing the resilience and reliability of products under dynamic mechanical forces. To ensure the success of shock testing, efficient control, and analysis techniques are indispensable. Here are some key aspects to consider:

Source: VR

Data Acquisition and Analysis

High-speed data acquisition systems are paramount in capturing accurate and detailed data during a shock test. These systems record essential parameters such as acceleration, displacement, and force with precision and at high sampling rates. The data acquired provides valuable insights into how the test item responds to the shock, facilitating a comprehensive analysis.

Real-world Example: In aerospace engineering, during the shock testing of satellite components, high-speed data acquisition systems capture data related to the structural integrity of the components when subjected to shock. This data aids in assessing whether the components can withstand the forces experienced during rocket launches.

Analysis of Weaknesses and Design Improvements

Data analysis is a crucial step in classical shock testing. It involves scrutinizing the acquired data to assess how the test item performed under shock conditions. By examining the response of the product, engineers can identify weaknesses, structural flaws, or design inefficiencies. This analysis guides the refinement of product designs and leads to enhanced reliability.

Fixture Design

The fixture that holds the test item on the shaker platform is a critical element in classical shock testing. It must be meticulously designed to accurately replicate real-world conditions. A poorly designed fixture can introduce unwanted resonances or inaccuracies into the test results, undermining the validity of the test.

Real-world Example: In the automotive industry, when conducting shock tests on vehicle components like suspensions, the fixture must replicate the actual mounting points and conditions within a vehicle. A well-designed fixture ensures that the test accurately simulates the forces experienced during normal vehicle operation.

Reproducibility and Repeatability

Reproducibility and repeatability are fundamental aspects of classical shock testing. Reproducibility ensures that the shock test setup can be replicated consistently, while repeatability implies that conducting the same test multiple times yields consistent results. This reliability is essential for assessing product performance accurately and making informed design decisions.

Test Documentation

Thorough test documentation is a cornerstone of effective shock testing. Engineers and researchers must meticulously record all aspects of the shock test, including the test setup, parameters, results, and any observations. This documentation serves several critical purposes:

Quality Control: Detailed documentation allows for quality control during and after the test, ensuring that procedures were followed correctly.

Future Reference: The documentation serves as a reference for future tests, comparisons, and improvements. It enables researchers to trace the evolution of product designs and testing methodologies.

Certification and Compliance: In many industries, documentation is essential for certification and compliance with industry standards and regulations. Proper documentation provides the evidence required for product certification.

Efficient control and analysis techniques are indispensable for the success of classical shock testing. High-speed data acquisition systems, meticulous fixture design, reproducibility, repeatability, and comprehensive test documentation collectively contribute to the accuracy and reliability of shock test results. By diligently implementing these techniques, engineers and researchers can assess product performance, identify weaknesses, and make informed design enhancements, ultimately ensuring the durability and safety of products across a spectrum of industries.

Shock testing, especially classical shock tests on electrodynamic shakers, plays a vital role in ensuring product reliability and safety. The choice of shock parameters, meticulous fixture design, and systematic test execution are critical for obtaining accurate and repeatable results. Data analysis identifies weaknesses and informs design improvements. By following these procedures, engineers and researchers can effectively evaluate a product's ability to withstand sudden mechanical forces, ultimately contributing to enhanced product quality across a range of industries.

Reach Us Now To Discuss Our Shock Test System!